Catalogue

Showing all 253 results

-

Amran

Amran 600V Low Voltage (LV) Ground Fault Current Transformers (CTs)

Amran 600V Low Voltage (LV) Ground Fault Current Transformers (CTs) are used to detect ground fault currents in switchgears, metering panels, and control panels. These ground fault CTs are available with large window sizes in rectangle or round shapes, and have three different encapsulation choices. Each product is tested for all routine tests specified by the standards. Amran Instrument Transformers are tested 100% at final stage before shipping. Final tests are carried out per IEEE C57.13 or IEC 60044, or relevant test standards, and all records are traceable by serial and batch numbers.

-

Amran

Amran 600V Low Voltage (LV) Single or Three Phase Potential Transformers (PTs), Voltage Transformers (VTs)

Amran 600V Low Voltage (LV) Potential Transformers (PTs), or voltage transformers (VTs), are available in single phase or three phase designs. These low voltage PTs are offered in many different sizes with or without mounting brackets, and are available with single and multi secondary options. Each product is tested for all routine tests specified by the standards. Amran Instrument Transformers are tested 100% at final stage before shipping. Final tests are carried out per IEEE C57.13 or IEC 60044, or relevant test standards, and all records are traceable by serial and batch numbers.

-

Amran

Amran 600V Low Voltage (LV) Split Core Current Transformers (CTs)

Amran 600V Low Voltage (LV) Split Core Current Transformers (CTs) are used in metering, and energy management applications. They are easily installed on long primary conductors, and voltage output is possible with a built in resistor. These split core CTs are available in standard or custom solutions with various construction options, a wide selection of windows and sizes, and many ratios starting from 50:5A.

-

Amran

Amran 600V Low Voltage (LV) Switchgear, General Purpose Current Transformers (CTs)

Amran 600V Low Voltage (LV) Switchgear and General Purpose Current Transformers (CTs) are designed and developed for OEM specific equipment. These CTs can be supplied with or without a secondary resistor, and are available in accuracy classes to meet application needs. Amran offers these current transformers in may different sizes, and with vaious construction options to meet your project specifications. Each product is tested for all routine tests specified by the standards. Amran Instrument Transformers are tested 100% at final stage before shipping. Final tests are carried out per IEEE C57.13 or IEC 60044, or relevant test standards, and all records are traceable by serial and batch numbers.

-

Amran

Amran Medium Voltage (MV) Single Phase Potential Transformers (PTs), Voltage Transformers (VTs)

Amran Medium Voltage (MV) Single Phase Potential Transformers are available in either single bushing or two bushing designs. These potential transformers (PTs), or voltage transformers (VTs), are easy to install, and are available in a wide ranges of sizes, with or without mounting brackets. Each product is tested for all routine tests specified by the standards. Amran Instrument Transformers are tested 100% at final stage before shipping. Final tests are carried out per IEEE C57.13 or IEC 60044, or relevant test standards, and all records are traceable by serial and batch numbers.

-

Amran

Amran Medium Voltage (MV) Switchgear Current Transformers (CTs)

Amran Medium Voltage (MV) Switchgear Current Transformers (CTs) are specifically designed to mount in medium voltage switchgears, usually 5, 15, 27, and 38kV switchgears. The CTs are normally mounted over primary bushings in MV switchgears, and they have integrated corner mounting holes for easy installation. These Amran MV switchgear CTs meet IEEE/ANSI C57.13, or IEC 61819-1 accuracy classes for metering and/or relaying. A wide range of windows, sizes and ratios are available.

-

Apollo

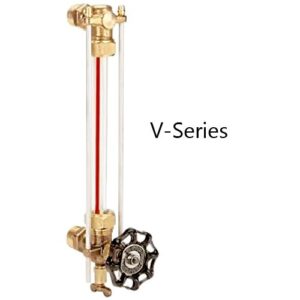

Apollo Valves 20-100, 20-200, 20-300 Series Bronze Liquid Level Gauges, Water Gauges

The Apollo® 20 Series Bronze Liquid Level Gauges, or water gauges, meet ASME design requirements, and are for use on all types of liquid level verification. These liquid level gauge sets are available in many variations including heavy bronze body patterns for higher service ratings, and with aluminum or plastic composite handles. An Apollo® standard liquid level gauge set includes top and bottom valves, sight glass, coated steel guard rods, and a 1/4″ drain valve. The Apollo® 20-100 series fits pipe sizes 3/8″ or 1/2″, the 20-200 series fits pipe sizes 3/8″ through 3/4″, and the 20-300 series is available in 1/2″ or 3/4″ pipe sizes. Made in the USA.

-

Ashcroft

Ashcroft 1005H Commercial Pressure Gauge

The Ashcroft® 1005H series pressure gauge combines an aesthetic design with reliability and performance. Easily customizable, the extensive variety of case materials, connection locations and ranges, make this model an ideal solution for many pressure measurement installations.

-

Ashcroft

Ashcroft 1005P Commercial Pressure Gauge

The Ashcroft® 1005P series pressure gauge combines an aesthetic design with reliability and performance. Easily customizable, the extensive variety of case materials, connection locations and ranges, make this model an ideal solution for many pressure measurement installations.

-

Ashcroft

Ashcroft 1005S Commercial Pressure Gauge

The Ashcroft® 1005S series pressure gauge combines an aesthetic design with reliability and performance. Easily customizable, the extensive variety of case materials, connection locations and ranges, make this model an ideal solution for many pressure measurement installations.

-

Ashcroft

Ashcroft 1008A-AL Pressure Gauge

The Ashcroft® 1008A-AL pressure gauge offers exceptional quality, durability, and performance. The sealed case protects from ambient conditions, and includes features enhancing product performance and safety. An ideal gauge for satisfying applications with high levels of vibration, pulsation, and pressure spikes.

-

Pressure guages

Ashcroft 1008S Stainless Steel Pressure Gauge

The Ashcroft® 40mm, 50mm, 63mm, 100mm 1008S pressure gauges are an excellent solution for pressure measurement in harsh environments. These gauges offer exceptional quality and reliability in an all stainless steel pressure gauge. The sealed case protects from ambient conditions and includes features enhancing product performance and safety. The 40 / 50mm gauges are ideal for limited space installations.

-

Ashcroft

Ashcroft 1009 2 1/2″, 3 1/2″ Duralife® Stainless Steel Case Pressure Gauges

The Ashcroft® 1009 Duralife® stainless steel case pressure gauge offers exceptional quality, durability, and performance. The removable bayonet ring allows the user easy access for minor adjustments. An ideal choice for satisfying most applications and installation requirements.

-

Ashcroft

Ashcroft 1009 4 1/2″, 6″ Stainless Steel Case Pressure Gauges

The Ashcroft® 1009 is an ASME style pressure gauge suitable for applications requiring a stainless steel case in a 4 1/2″ or 6″ size. The 1009 provides durability, reliability and performance with protective features for corrosive or other challenging process media applications.

-

Ashcroft

Ashcroft 1020S Christmas Tree Pressure Gauge

The Ashcroft® 1020S christmas tree pressure gauge is used specifically within oil and gas fields. This model requires minimal field maintenance due to its design, providing a safe and reliable instrument platform. An ideal pressure gauge for satisfying challenging offsore rings or wellhead applications.

-

Ashcroft

Ashcroft 1032 Fractional Sanitary Pressure Gauge

The Ashcroft® 1032 fractional sanitary gauge is used for satisfying stringent compact sanitary requirements. It is available with material traceable certification to EN 10205: 2004 3.1. An electropolished diaphragm and housing make it an ideal solution for applications in the food, pharmaceutical and bio-technical industries.

-

Ashcroft

Ashcroft 1032 Sanitary Pressure Gauge

The Ashcroft® 1032 sanitary gauge is 3A approved and is designed specifically to satisfy stringent sanitary requirements. An ideal instrument that ensures reliability and process integrity for the food, pharmaceutical and bio-technical industries.

-

Ashcroft

Ashcroft 1036 Sanitary Pressure Gauge

The Ashcroft® 1036 inline 3A approved sanitary gauge satisfies stringent sanitary requirements with its unique design. Mated with the type 1037 Inline fitting, this assembly virtually eliminates process deadleg, assuring contamination is minimized. An ideal instrument for reliability and process integrity. Available with material traceable certification to EN 10205: 2004 3.1. An electropolished diaphragm and housing make it an ideal solution for applications in the food, pharmaceutical and bio-technical industries.

-

Ashcroft

Ashcroft 1082 Test Pressure Gauge

The Ashcroft® 1082 test gauge is a precise instrument acclaimed for dependability, safety and performance. Used for test and validation, its manufacture is continuously monitored to assure uncompromising standards and material integrity. An ideal choice for satisfying most applications and installation requirements needing highly-reliable precision instruments.

-

Ashcroft

Ashcroft 1125 Differential Pressure Gauge

The Ashcroft® 1125 gauges offer an economical solution for measuring high differential pressures for non-corrosive applications such as water, air or hydraulics and featuring a robust Aluminum case.

-

Ashcroft

Ashcroft 1127 Differential Pressure Gauge

The Ashcroft® 1127 gauges offer a solution for measuring high differential pressures for applications requiring stainless steel wetted materials and aluminum case.

-

Ashcroft

Ashcroft 1128 Differential Pressure Gauge

The Ashcroft® 1128 gauge offers a solution for measuring high differential pressures for applications requiring stainless steel wetted materials and aluminum case.

-

Ashcroft

Ashcroft 1130 Differential Pressure Gauge

The Ashcroft® 1130 gauge is a very economical means for measuring differential pressure in applications where media migration may be acceptable such as lubrication, flow monitoring and tank level indication.

-

Ashcroft

Ashcroft 1187 Low Pressure Bellows Gauge

The Ashcroft® 1187 bellows gauge is used when a ASME type low pressure panel gauge is required. Its highly sensitive system and standard product features are available to meet many process applications. Available with diaphragm seals, this is an ideal instrument solution for many installation points.

-

Ashcroft

Ashcroft 1188 Low Pressure Bellows Gauge

The Ashcroft® 1188 bellows gauge is used when an ASME style low pressure gauge is required. Its highly sensitive system and standard product features are available to meet many process applications. Available with diaphragm seals, this is an ideal product instrument solution for many installation points.

-

Ashcroft

Ashcroft 1189 Low Pressure Bellows Gauge

The Ashcroft® 1189 bellows gauge is used when a ASME style low pressure gauge with an aluminum case is required. Its highly sensitive system and standard product features are available to meet many process applications. Available with diaphragm seals, this is an ideal instrument solution for many installation points.

-

Ashcroft

Ashcroft 1209 Process Pressure Gauge

The Ashcroft 1209 is a process pressure gauge with a stainless steel case designed for applications requiring safety and reliability. It is a fundamental instrument used in various industries to monitor and control processes where maintaining specific pressure levels is crucial.

The 1209 pressure gauge prioritizes safety in challenging conditions. Its solid front case and ring, constructed from 316L stainless steel, coupled with a full pressure-relief back, guarantee that in the event of an internal failure. The process fluid is directed away from the operator, ensuring maximum safety.

The Ashcroft 1209 is a high performance pressure gauge with a 4 1/2″ dial size, solid front case, standard acrylic window (safety glass is optional), an adjustable aluminum micrometer pointer, ranges up to 20,000 psi (1,400 bar),and complies with ASME B40.100.

Also, the 1209 stainless steel case process pressure gauge has the option of the patented PLUS! Performance which dampens vibration, shock and pulsation effects!

The 1209 process pressure gauge from Ashcroft is an indispensable tool that provides critical information for ensuring safety, efficiency, and compliance in a wide range of applications. It is a fundamental instrument for anyone involved in system monitoring, maintenance, and optimization.

-

Ashcroft

Ashcroft 1209-XRA Stainless Steel High Overpressure Process Pressure Gauge

The Ashcroft® 1209-XRA is a high performance 4 1/2″ ASME style Process pressure gauge with a stainless steel case designed for applications requiring safety and reliability. The 1209-XRA protects when sudden pressure surge occurs at start-up or during process pressure spikes.

-

Ashcroft

Ashcroft 1259 Process Pressure Gauge

The Ashcroft® 1259 is an economical 4 1/2″ ASME style process pressure gauge featuring Stainless Steel or Monel® Wetted materials designed with numerous safety features. The 1259 features a solid front case design, and ranges from vacuum to 20,000psi/(1400 bar).

-

Ashcroft

Ashcroft 1279 Duragauge® Process Pressure Gauge

The Ashcroft® 1279 Duragauge® is a high performance 4 1/2″ ASME style process pressure gauge with a comprehensive design for maximizing safety and reliability. This process pressure gauge features a solid front case and a 10 year warranty on the pressure system.

-

Ashcroft

Ashcroft 1377 Duragauge® Process Pressure Gauge

The Ashcroft® 1377 Duragauge® is a high performance ASME style Process pressure gauge with sizes from 4 1/2″ to 8 1/2″ designed for panel mounting. Features include a solid front aluminum case and a 10 year pressure system warranty.

-

Ashcroft

Ashcroft 1379 Duragauge® Process Pressure Gauge

The Ashcroft® 1379 Duragauge® is a high performance ASME style pressure gauge with sizes from 4 1/2″ to 8 1/2″ with numerous safety features and ranges up to 100,000 psi. Features include a solid front aluminum case and a 10 year pressure system warranty

-

Ashcroft

Ashcroft 1490 Low Pressure Diaphragm Gauge

The Ashcroft® 1490 diaphragm gauge is a cost effective solution for low pressure measurement applications. It provides reliability and accurate performance due to its ultra-sensitive diaphragm measuring system. An ideal gauge for non-corrosive gas measurement.

-

Ashcroft

Ashcroft 2008 Panel Builders Pressure Gauge

The Ashcroft® 2008 panel builders pressure gauge is designed for easy installation in equipment panels. Providing exceptional quality, durability, and performance, it is an ideal product for many installations and will easily retrofit into existing panels.

-

Ashcroft

Ashcroft 2030 Series Digital Sanitary Pressure Gauges

The Ashcroft® 2030 series digital sanitary pressure gauges are multifunctional instruments providing exceptional features and performance. Conventional or inline style Tri-Clamp® connections allow gauges to be cleaned or steamed in place in sanitary applications. An ideal indicator for satisfying many pharmaceutical, biotech or food processing applications. Model 203X is battery powered, model 213X is 4-20 mA loop powered and model 223X is powered by 12-36vdc with options for switch output and 4-20 mA output.

-

Ashcroft

Ashcroft 2074, 2174, 2274 Digital Pressure Gauges

The Ashcroft® 2074, 2174 and 2274 digital pressure gauge multifunctional instrument providing exceptional features and performance. Model 2074 is battery powered, model 2174 is 4-20mA loop powered, and model 2274 is powered by 12-36vdc with options for switch output and 4-20 mA output. Polysilicon thin film technology makes pressure measurement extremely reliable and virtually unaffected by shock and vibration. An ideal indicator for industrial test and measurement applications.

-

Ashcroft

Ashcroft 2084, 2086, 2089 Digital Test Gauges

The Ashcroft® 2084, 2086, and 2089 digital test gauges are highly accurate test instruments providing exceptional features and performance. The full scale total error (TEB) includes the effects of linearity, hysteresis, repeatability and temperature from 0 to 150°F. Silicone MEMS sensor technology provides accuracy and long term stability demanded by test Iinstrumentation users. An ideal indicator for test and measurement applications.

-

Ashcroft

Ashcroft 8008A Stainless Steel Case Commercial Pressure Gauge

The Ashcroft® 8008A pressure gauge is designed to meet both EN837-1 and ASME B40.100, ensuring accuracy and long term performance. This high quality pressure gauge is easily retrofitted and offered with custom dial scales and logos. A perfect choice for hydraulic systems, compressors and many other OEM applications.

-

Ashcroft

Ashcroft 8008S Stainless Steel Case Pressure Gauge

The Ashcroft® 8008S delivers the advanced features of a larger gauge in a small, economical package for applications requiring an all stainless steel instrument for harsh environments. Laser welded wetted 316L stainless steel components ensure system integrity for corrosive medias. A solid front case option is also available to enhance operator safety along with numerous mounting selections to save space and ease installation.

-

Ashcroft

Ashcroft 8009S Stainless Steel Pressure Gauge

The Ashcroft 8009S stainless steel pressure gauge delivers the advanced features of a larger gauge in a small, economical package for applications requiring an all stainless steel instrument for harsh environments.

The pressure gauge’s laser welded wetted 316L stainless steel components ensure system integrity for corrosive medias.

The 8009S pressure gauge has a removable bayonet ring that allows the user easy access for minor adjustments.

This pressure gauge can be used in hydrogen cell and H2 gas applications.

-

Ashcroft

Ashcroft BI Bimetal Thermometer

The Ashcroft® model BI economical bimetallic thermometer has silicone coil dampening (up to 400°) which provides vibration dampening, and has a hermetically sealed case which prevents entry of moisture, interior corrosion and coil freeze-up. This model also has a heavy-duty glass lens with Maxvision® dial which allows for readability from any angle without parrallax error.

-

Ashcroft

Ashcroft C-600A-01 Duratemp® Gas Actuated Thermometer

The Ashcroft® C-600 A Duratemp® gas actuated thermometer is a remote or panel mounted process instrument providing maximum durability while being highly resistant to shock and vibration. This thermometer’s remote mount capabilities allows operators to monitor process temperatures while staying away from unsafe applications. Usually recommended with a thermowell, the Duratemp® is ideal for installations subject to vibration, hazardous process media, and extreme temperatures.

-

Ashcroft

Ashcroft C-600A-02 Duratemp® Gas Actuated Thermometer

The Ashcroft® C-600 A Duratemp® gas actuated thermometer is a remote or panel mounted process instrument providing maximum durability while being highly resistant to shock and vibration. This thermometer’s remote mount capabilities allows operators to monitor process temperatures while staying away from unsafe applications. Usually recommended with a thermowell, the Duratemp® is ideal for installations subject to vibration, hazardous process media, and extreme temperatures.

-

Ashcroft

Ashcroft C-600A-03 Duratemp® Gas Actuated Thermometer

The Ashcroft® C-600 A Duratemp® gas actuated thermometer is a remote or panel mounted process instrument providing maximum durability while being highly resistant to shock and vibration. This thermometer’s remote mount capabilities allows operators to monitor process temperatures while staying away from unsafe applications. Usually recommended with a thermowell, the Duratemp® is ideal for installations subject to vibration, hazardous process media, and extreme temperatures.

-

Ashcroft

Ashcroft C-600A-04 Duratemp® Gas Actuated Thermometer

The Ashcroft® C-600 A Duratemp® gas actuated thermometer is a remote or panel mounted process instrument providing maximum durability while being highly resistant to shock and vibration. This thermometer’s remote mount capabilities allows operators to monitor process temperatures while staying away from unsafe applications. Usually recommended with a thermowell, the Duratemp® is ideal for installations subject to vibration, hazardous process media, and extreme temperatures.

-

Ashcroft

Ashcroft C-600B Duratemp® Gas Actuated Thermometer

The Ashcroft® C-600 B Duratemp® gas actuated thermometer is a direct-mount process instrument providing maximum durability while being highly resistant to shock and vibration. Its high and low temperature range capability exceeds that of most bimetallic thermometers, making it ideal for use on many extreme applications. Usually used with a thermowell, the Duratemp® is ideal for installations subject to vibration, hazardous process media, and extreme temperatures.

-

Ashcroft

Ashcroft C-600H-45 Duratemp® Gas Actuated Thermometer

The Ashcroft® C-600 A Duratemp® gas actuated thermometer is a remote or panel mounted process instrument providing maximum durability while being highly resistant to shock and vibration. This thermometer’s remote mount capabilities allows operators to monitor process temperatures while staying away from unsafe applications. Usually recommended with a thermowell, the Duratemp® is ideal for installations subject to vibration, hazardous process media, and extreme temperatures.

-

Ashcroft

Ashcroft CI Industrial Bimetal Thermometer

The Ashcroft® model CI industrial bimetallic thermometer is a high quality tamperproof temperature instrument that delivers exceptional reliability. An ideal choice for accurate temperature readings.

-

Ashcroft

Ashcroft DG25 General Purpose Digital Pressure Gauge

The Ashcroft® DG25 general purpose digital pressure gauge provides exceptional performance, stability and reliability. The laser welded stainless steel sensor and socket make this indicator suitable for use with a wide variety of pressure media in demanding industrial applications. The DG25 was designed with OEM in mind and can easily be custom configured to meet unique requirements.

-

Ashcroft

Ashcroft EL Industrial Bimetal Thermometer

The Ashcroft® model EL industrial bimetallic thermometer is a high-quality process temperature instrument that delivers exceptional reliability. The EL model is satisfactory for continuous service up to 800°F (425°C), and can be used for intermittent service from 800 to 1,000°F (425 to 500°C).

-

Ashcroft

Ashcroft GT-Series NEMA 4 316 SS Multifunction Watertight Temperature Switches

The Ashcroft® GT NEMA 4 temperature switch is engineered for use in tough applications requiring a 316L Stainless steel enclosure. The simple design allows for easy wiring and field installation, while proven technology delivers repeatable, long-term performance. With temperature ranges from-40°F to 750°F this switch is ideal for temperature control, shutdown or alarm operations.

-

Ashcroft

Ashcroft HPT Teflon Pressure Gauge – 63mm

The Ashcroft® 63mm HPT anti-corrosion pressure gauge offers exceptional performance and reliability for chemical delivery systems within the semiconductor and electronic fabrication industries. Nitrogen leak tested to ensure superior quality, while the compact design is ideal for limited space installations.

-

Ashcroft

Ashcroft HPX High Purity Pressure Gauge – 50mm, 63mm

The Ashcroft® 50mm, 63mm HPX high purity pressure gauges are ultrasonically cleaned to provide exceptional quality and reliability in ultra high-purity gas delivery systems. Its stainless construction and wetted components prove ideal for use with industrial gases in semiconductor and electronic manufacturing.

-

Ashcroft

Ashcroft HPX Miniature High Purity Pressure Gauge – 28mm

The Ashcroft® 28mm HPX miniature high purity pressure gauge offers exceptional performance and reliability for ultra high-purity gas delivery systems within the semiconductor and electronic fabrication industries. Ultrasonic cleaning and helium leak testing ensure superior quality, while the compact design facilitates high-density mounting.

-

Ashcroft

Ashcroft K Dual Sensor Thermometer

The Ashcroft® Model K Dual Sensor thermometer provides a high quality product with reliable performance from the combination of a Bimetal and a K Thermocouple. Two independent sensors providing accurate temperature readings with dampening options when vibration is present. An ideal choice for reducing installation costs and providing an added space reduction benefit.

-

Ashcroft

Ashcroft LT-Series NEMA 4 Watertight Multifunction Temperature Switches

The Ashcroft® LT NEMA 4 temperature switch is engineered for use in virtually all OEM and industrial applications. The simple design allows for easy wiring and field installation, while its proven technology delivers repeatable, long-term performance. With temperature ranges from-40°F to 750°F this switch is ideal for temperature control, shutdown or alarm operations.

-

Ashcroft

Ashcroft PT-Series NEMA 7 & 9 Explosion Proof Temperature Switches

The Ashcroft® PT NEMA 9 explosion proof temperature switch is designed for use in harsh applications where hazardous approvals and uncompromising safety is required. The PT switch proven technology provides a stable, long-lasting product that can be used over a wide range of temperatures. It is field proven for extreme reliability and is ideal for pressure control, shutdown or alarm operations in hazardous locations.

-

Ashcroft

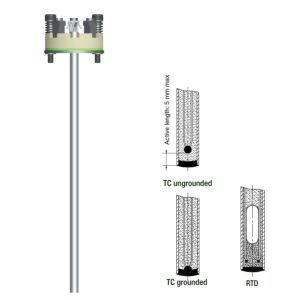

Ashcroft S01 RTD & Thermocouple DIN Inserts, Mineral Insulated Probe Insert Assemblies

The Ashcroft® S01 inserts have sensors with a mineral insulated metal sheath. There are two types: resistance temperature detectors (RTDs) or thermocouples (TCs). In each case, the sensor supplies an electrical signal corresponding to the temperature. Integral DIN style terminal block and transmitter designs. The travel of this spring mounting assures best thermal conductivity, compensation of length tolerances in thermowells and protection against vibration. When mounted in thermowells, inserts can be simply replaced, without removing the thermowell from the pipe and without any process interruption.

-

Ashcroft

Ashcroft S10 RTDs & Thermocouples with Metric Connection, Temperature Sensor Assemblies

The Ashcroft® S10 temperature sensor assemblies provide accurate temperature measurements for most applications. Each temperature sensor assembly consists of a spring loaded temperature sensor insert, a connection head and lag extension. The S10 assembly may also include an optional terminal block for wiring and / or transmitters. Thermocouple assemblies are manufactured to either to IEC 60584-2 or ANSI MC 96.1, and RTD (resistance temperature detector) assemblies are manufactured to IEC 60751.

-

Ashcroft

Ashcroft S50 Industrial RTDs & Thermocouple with NPT Connections, Temperature Sensor Assemblies

The Ashcroft® S50 temperature sensor assembly provides accurate temperature measurements. Each temperature sensor assembly consists of a spring loaded temperature sensor, magnesium oxide, (MgO), insulated insert, connection head and lag extension. The S50 assembly may also include an optional terminal block and / or transmitters. Thermocouple assemblies are manufactured to IEC 60584-2 or ANSI MC 96.1, and RTD (resistance temperature detector) assemblies are manufactured to IEC 60751.

-

Ashcroft

Ashcroft S5500 Stainless Steel Gas Actuated Thermometer

The Ashcroft® S5500 gas actuated thermometer is a direct or remote mounted instrument providing performance while being highly resistant to shock and vibration. This product is extremely versatile for use on many applications. Usually used with a thermowell, the S5500 is ideal for applications with vibration and very high or low temperature.

-

Ashcroft

Ashcroft S70 Tube Skin Thermocouple Temperature Sensor Assembly

The Ashcroft® S70 temperature sensor assemblies provide accurate temperature measurements for applications that are located in hazardous environments. Each temperature sensor assembly consists of a temperature sensor, magnesium oxide, MgO, insulated insert, connection head and lag extension. The S70 assembly may also include an optional terminal block for wiring and / or transmitters. Thermocouple assemblies are manufactured to either to IEC 60584-2 or ANSI MC 96.1.

-

Ashcroft

Ashcroft SB Subsea Pressure Gauge

The Ashcroft® SB subsea pressure gauge provides exceptional durability for undersea environments. The fully-welded measurement system and materials of construction assures ensures reliability and corrosion resistance, while the various sizes and mounting serve many installation points to depths of 6,000 meters.

-

Ashcroft

Ashcroft SC Subsea Pressure Gauge

The Ashcroft® SC subsea pressure gauge provides exceptional durability for undersea environments. The fully-welded measurement system and materials of construction assures ensures reliability and corrosion resistance, while the various sizes and mounting serve many installation points to depths of 6,000 meters.

-

Ashcroft

Ashcroft T-Series NEMA 4X Watertight Temperature Switches

The Ashcroft® T4 NEMA 4X temperature switch is designed for use in virtually all OEM and industrial applications. With temperature ranges from-40°F to 750°F, the T4 delivers outstanding repeatability, this switch is ideal for temperature control, shutdown or alarm operations. The T4 switch is SIL 3 Capable for safety applications.

-

Ashcroft

Ashcroft T-Series NEMA 7 & 9 Explosion Proof Temperature Switches

The Ashcroft® T7 NEMA 7 & 9 explosion proof temperature Switch is designed for use in hazardous applications. With temperature ranges from-40°F to 750°F, the T7/9 delivers outstanding repeatability, this switch is ideal for temperature control, shutdown or alarm operations. The T7 switch is SIL 3 Capable for safety applications.

-

Ashcroft

Ashcroft T5500 Stainless Steel Pressure Gauge

The Ashcroft® T5500 pressure gauge designed to EN837-1 with an open front stainless steel case designed for high performance and reliability. Features include 100mm and 160mm sizes, PLUS! performance, and optional ATEX approvals.

-

Ashcroft

Ashcroft T6500 Stainless Steel High Pressure Gauge

The Ashcroft® T6500 is an process pressure gauge designed to EN837-1 with a solid front stainless steel case designed for high performance, increased safety and reliability. Features include 100mm and 160mm sizes, PLUS!™ performance, and optional ATEX approvals.

-

AW-Lake

AW-Lake Basic Inline Liquid Variable Area Flow Meter

The AW-Lake Basic Inline Liquid Variable Area Flow Meter is ideal for monitoring pump performance and oil or water flows through hydraulic circuits and cooling systems. Often referred to as rotameters, AW-Lake’s Basic variable area flow meters are a low cost alternative to other flow meter types and are available in numerous materials of construction, including aluminum, brass and stainless steel to meet system and media requirements. The superior design of this inline flow meter makes it not only weather-proof for outdoor environments and wash-downs, but also reliable with maintenance-free performance.

-

AW-Lake

AW-Lake Clamp-On Ultrasonic Transit Time Flow Meter

The AW-Lake Clamp-On Ultrasonic Transit Time Flow Meter fastens on the outside of vertical or horizontal pipes ranging in size from ½” through 48”. Housed in a water-and dust-tight NEMA4X polycarbonate enclosure, the Clamp-On Ultrasonic Flow Meters are compatible with a range of metal and plastic pipe materials and corrosive liquids that would damage standard flow meters. As a result, the non-intrusive, clamp-on ultrasonic sensors feature enhanced flow measurement with no pressure drop in a range of applications such as food or chemical processing plants, oil refineries, and more.

-

AW-Lake

AW-Lake Classic Series TCM TRICOR Coriolis Mass Flow Meters

The AW-Lake TCM CLASSIC Series of Coriolis Mass Flow Meters meets general industrial requirements with out-of-the-box ease of use. The lower cost and lower performance specs of the TCM Classic Series meets broader application needs. The TRICOR Coriolis Mass Flow Meters from TASI Flow are absolutely reliable and robust sensors in a variety of processes, performing multiple measurements simultaneously with customizable process parameters and multiple communication languages. The production team mechanically balances every meter, assuring the dual tubes are dynamically aligned and in perfect balance before flow begins. The unique design and cutting edge manufacturing procedures ensure a meter with the highest resistance to external influences.

-

AW-Lake

AW-Lake FlowStat Turbine Flow Sensor, Paddle Wheel Flow Meters

The AW-Lake FlowStat Paddle Wheel Flow Meters are used to monitor various fluids. This turbine flow rate sensor can be connected directly to analog acquisition cards, chart recorders or other monitoring instruments without external signal conditioning. The FlowStat flow rate meter integrates rugged tangential turbine technology with a precision digital to analog conversion circuit hermetically encapsulated within the body of the meter.

-

AW-Lake

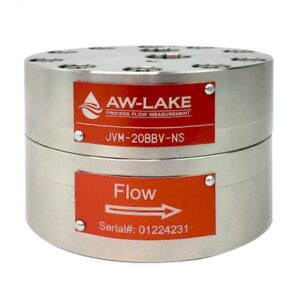

AW-Lake JV-BB Next-Gen Positive Displacement Gear Meter Flow Meter

The AW-Lake JV-BB Positive Displacement Flow Meter is part of the Next-Generation line of Gear Meters. These high performance flow meters have tighter machining tolerances, higher resolution, higher pressure rating, and improved accuracy over their predecessor, the JV-KG flow meter. As a result, operational costs are reduced. This flow meter maintains high accuracy and repeatability, despite changing viscosity conditions, up to ±0.25% accuracy with select sensors.

-

AW-Lake

AW-Lake TCMH 0450 High Pressure Hydrogen Coriolis Mass Flow Meters

The AW-Lake TCMH 0450 High Pressure Hydrogen Coriolis Mass Flow Meter is the world’s first MI-002 / OIML137 certified Coriolis flow meter for hydrogen dispensing and is offered in three pressure ratings: 6,000 psi, 10,000 psi and 15,200 psi. The U-shape tubes are made from Sandvik® Alloy HP 160, chosen to eliminate hydrogen embrittlement, such as in Hydrogen fueling stations.

-

Dwyer

Dwyer Series 1620 Single and Dual Pressure Switch

The Dwyer Series 1620 Single and Dual Pressure Switch is the best when the highest precision combined with diaphragm sealed leak-proof construction and mounting simplicity is required. The Dwyer Model 1626 and 1627 differential pressure switches are identical in design and construction, except that Model 1626 has a single electric switch and Model 1627 has dual electric switches.

A Dwyer Model 1627 Dual Pressure Switch can provide dual control when required and can be set to open or close two independent electrical circuits, each preset for its own actuation pressure.

Both Dwyer Series 1620 Pressure Switch models have diaphragm sealed motion take outs providing maximum protection against leakage.

-

Dwyer

Dwyer Series 2000 Magnehelic Differential Pressure Gages

The Dwyer Series 2000 Magnehelic Differential Pressure Gages is selected for a versatile low differential pressure gage with a wide choice of 81 models and 27 options to choose from. Using Dwyer’s simple, frictionless Magnehelic® gage movement, it quickly indicates air or non-corrosive gas pressures – either positive, negative (vacuum) or differential. The design resists shock, vibration, over-pressures and is weatherproof to IP67.

The Dwyer Series 2000-HA High Accuracy Magnehelic Differential Pressure Gages are twice as accurate as the standard Magnehelic® gages. The well-engineered high accuracy Magnehelic® gage offers a mirrored overlay as standard in order to eliminate any parallax error when taking measurements. A six point calibration certificate is included with each high accuracy model. The rugged IP67 casing helps fully protect against dust and water ingress. The redesigned corrosion resistant brushed 304 stainless steel bezel option offers a clean tapered design, yet minimizes the possibility of any dust accumulation on the edges.

-

Dwyer

Dwyer Series 4000 Capsuhelic Differential Pressure Gages

The Dwyer Series 4000 Capsuhelic Differential Pressure Gages are designed to give fast, accurate indication of differential pressures. The Capsuhelic® Differential Pressure Gage may be used as a readout device when measuring flowing fluids, pressure drop across filters, liquid levels in storage tanks and many other applications involving pressure, vacuum or differential pressure. The pressure being measured is held within a capsule which is an integral part of the gage. This containment of the pressure permits the use of the gage on system pressures of up to 500 psig, even when differentials to be read are less than 0.1 in w.c.

The Dwyer Series 4000 Capsuhelic Differential Pressure Gages may be used with hydrogen where pressures are less than 35 psi, and should be ordered with a Buna-N diaphragm. The Series 4000 Capsuhelic gages are available with optional forged brass housing for water or water based fluids, adjustable signal flags, NIST traceable calibration certificate, and red, green, mirrored or combination scale overlays.

-

Dwyer

Dwyer Series RM Rate-Master Polycarbonate Flowmeters

The Dwyer Series RM Rate-Master Flowmeters are a line of general use, direct reading precision flowmeters suitable for both gas and liquid applications. The RM Rate-Master® Polycarbonate Variable Area Flowmeter Series consists of 2″, 5″ and 10″ scales that can be panel or surface mounted with optional precision metering valves. The Rate-Master flowmeter bodies can be instantly interchanged within the same series scale size, allowing the piping to remain undisturbed, interchangeability of the ranges, and easy cleaning.

The Dwyer Series RM Rate-Master® Polycarbonate Flowmeters are available with optional adjustable pointer flags which provide a quick visual reference to a required flow level. Made of clear plastic, the pointer flags snap into place inside the bezel and slide to the desired level. The RM Rate-Master Polycarbonate Flowmeters are also available with an optional NIST traceable calibration certificate.

-

Eaton

Eaton 5P UPS, Lithium-ion Rackmount, Lead-Acid Tower & Rackmount

The Eaton 5P Uninterruptible Power Supply (UPS) is an enterprise-class backup power solution available as a tower UPS, wall mount UPS, and rackmount UPS. Several models are available as a compact UPS–which are 2U in height with shorter depths than a traditional UPS–making them perfect for 4-post or 2-post rail and wall mounting. The 5P UPS even offers flexibility in battery types with two models offering lithium-ion batteries. Complete your backup power solution by pairing a 5P UPS with an Eaton Gigabit Network card–the first in the industry to comply with the UL and IEC cybersecurity standards–and the Brightlayer Data Centers suite software for seamless management of your connected equipment.

-

Eaton

Eaton 5PX G2 UPS 1–3 kVA Tower & Rackmount Battery Backup

The Eaton 5PX G2 rackmount and tower UPS provides the maximum power possible at each power rating. The 5PX G2 UPS has power ratings ranging from 1 to 3 kVA, with low and high voltage options and offers up to four optional external battery modules for extra runtime. With select 2 and 3 kVA models, the 5PX G2 UPS offers a reduced depth that conserves space for high density wallmount rack installations.

-

Eaton

Eaton 5PX UPS Enterprise Class Lead-Acid Tower & Rackmount Battery Backup

The Eaton 5PX Uninterruptible Power Supply (UPS) features the connection of up to four extended battery modules (EBMs) for maximum runtime and premium backup of your professional and enterprise-grade servers, storage and networking equipment. The 5PX is available in a convertible form factor for use as a tower UPS or rackmount UPS to ensure a perfect fit for a variety of applications. This extended runtime UPS is also available in convenient bundles with a network card and management software for rapid integration into your virtual environment or hyperconverged infrastructure. The 5PX warranty covers both the UPS and the batteries for three years.

-

Eaton

Eaton 5S UPS, 120V, 230V, 50 / 60 Hz Desktop / Tower Uninterruptible Power Supply

The Eaton 5S Uninterruptible Power Supply (UPS) displays critical UPS information on battery time and outage tracking through an available, user-friendly LCD interface.

The Eaton 5S desktop UPS also provides surge protection for your network data line and coax cable connection.

The versatile 5S UPS can be used as a tower or as a desktop monitor stand, and comes with a standard three-year warranty on the UPS and batteries along with a $150,000 load protection guarantee for all of your connected equipment.

-

Eaton

Eaton 9355 UPS (Powerware 9355 UPS) 10-30 kVA Mid-sized Three-Phase Uninterruptible Power Supply

Discover the Eaton 9355 Three-Phase UPS, formerly known as the Powerware 9355 Three-hase UPS, for critical battery backup power solutions! This cutting-edge, double-conversion, online battery backup UPS delivers complete power protection. With a footprint up to 75% smaller than similar UPS models, this powerhouse includes internal batteries, an integrated power distribution module, and a maintenance bypass switch.

Unlike other models, the Eaton 9355 UPS eliminates the need for large external battery cabinets. Using Eaton’s patented HotSync technology, you can seamlessly parallel up to four UPSs. This offers superior redundancy or additional capacity without the space constraints of a typical large UPS.

Reduce installation costs with the on-board plug-and-play power distribution module which allows for 15 different output receptacles. For complete power protection, isolate expensive IT equipment from all nine of the most common power issues with double-conversion topology.

Experience Eaton’s industry-leading blend of flexibility, scalability, and power density housed in an innovative, highly efficient package. Optimize your backup power infrastructure with this space-saving, reliable solution. Though Eaton has rebranded the Powerware 9355 Three-Phase UPS, they maintain the same reliability and performance standards.

-

Eaton

Eaton 9PX 6 kVA Lithium-ion UPS, Single Phase/Double Conversion Uninterruptible Power Supply

The Eaton 9PX Lithium-ion Uninterruptible Power Supply (UPS) features a 6 kVA power rating, remote firmware upgrades, and comes in rackmount or tower for factors. This model has the same reliable features as the lead-acid UPS, including load segments that allow for prioritized shutdown, remote power on (RPO), remote on / off (ROO) and output relay ports that increase control capabilities.

-

Eaton

Eaton 9PX Lithium-ion UPS, Single Phase/Double Conversion UPS

The Eaton 9PX lithium-ion Uninterruptible Power Supply (UPS) is part of the Eaton 9 series single-phase double-conversion UPS line, best applied to mission-critical equipment for constant power conditioning. The 9PX lithium-ion rackmount and tower UPS provides 8 to 10 years of life expectancy for UPS and its batteries, and has power ratings ranging from 1 to 3 kVA, while also offering up to four external battery modules (EBM) for extra runtime. The 9PX lithium-ion UPS has the same reliable features as the 9PX lead-acid UPS, including load segments for prioritized shutdowns, remote power on (RPO), remote on / off (ROO) and output relay ports that increase control capabilities. For connectivity, the 9PX is compatible with the Gigabit Network Card (NETWORK-M2), which is the first UPS connectivity device to meet both UL and IEC cybersecurity standards. This network interface card improves power system reliability by providing warnings of pending issues and helping to perform an orderly shutdown of servers and storage.

-

Eaton

Eaton 9PX UPS 5, 6, 8 & 11kVA Three Phase Input / Single Phase Output UPS & Single Phase UPS

The Eaton 9PX Uninterruptible Power Supply (UPS) delivers premium backup power and scalable battery runtimes for servers, voice / data networks, and storage systems making it the ideal solution for both rack and stand-alone installations. The Eaton 9PX UPS constantly monitors power conditions and regulates voltage and frequency. The graphical LCD provides clear information on the UPS’s status and measurements on a single screen, and the display position can be adjusted to offer the best viewable angle for tower and rack usage. The 9PX allows you to connect more devices by providing up to 28% more wattage compared to traditional UPSs.

-

Eaton

Eaton 9PXM UPS 4-20kVA

The Eaton 9PXM Uninterruptible Power Supply (UPS) is a scalable, modular UPS that combines the highest levels of reliability and the lowest total cost of ownership. Eaton’s 9PXM enables you to build a mission critical power solution specific to your needs. Its patented design allows you to add capacity or redundancy, and increase runtime as your power needs change. The plug-and-play power and battery modules are lightweight and user replaceable so you can add them as needed without a service call or having to put a redundant system in bypass. The 9PXM’s 20kVA N+1 capacity, small footprint and easy rack conversion make it an ideal solution for an array of data center, mission critical, and retail applications. The design offers harmonious compatibility with 4-post or high density racks, PDU’s and network gear for seamless integration into existing IT infrastructure.

-

Battery Monitors Meters

Electroswitch Arga Series 1000 Utility Substation Battery Monitor, Panel Mount, Rack Mount, and Portable

The Electroswitch Arga Series 1000 Utility Substation Battery Monitor is a breakthrough in battery monitoring, and ground fault detection. This highly accurate instrument is powered by the same battery it monitors. It displays battery bus voltage, ripple voltage, ripple current (with an optional clamp-on sensor 25-1100-H1) +Bus voltage to GND,-Bus voltage to GND faults, and high impedance faults based on ripple voltage and ripple current. Mounting options for the Series 1000 Arga Battery Monitor include panel mount, or 19″ rack mount (3U or 4U), and portable for single or dual units. These battery monitors have ground fault locator, and corrosion detection options available.

-

Electrical Solutions

Electroswitch Series 24 3-Phase TCM, Trip Coil Monitor

The Electroswitch Series 24 Three-Phase TCM, Trip Coil Monitor, provides continuous monitoring of each phase of a Breaker Trip Coil. The TCM is a convenient panel-mounted relay that provides continuous monitoring of trip coils, and 52B auxiliary contacts utilizing 3 bi-color LEDs for visual indication of trip coil and breaker position status for each phase. The Series 24 TCM monitors the individual phases from each trip coil power supply, thereby meeting the Northeast Power Coordinating Council’s requirements for the monitoring of a single-pole tripping to ensure proper breaker operation should there be a single trip coil failure.

-

Electrical Solutions

Electroswitch Series 24 ATR, Annunciator Target Relay

The Electroswitch Series 24 ATR, Annunciator Target Relay, is a solid state device designed for use in a variety of utility and industrial applications. It provides a highly visible LED indication of a trip operation, and activates other equipment within the system such as alarms, LORs, and other relay devices. The Series 24 ATR accepts a 37-140VDC Trip input signal from a variety of devices. When a Trip signal is received, the ATR performs two basic functions. First, it illuminates a bright LED indicating that a Trip signal has indeed been received. Second, it closes two normally open auxiliary contacts rated at 2 Amps @ 125VDC continuous (8A for 1 second).

-

Electrical Solutions

Electroswitch Series 24 CSR, Control Switch Relay

The Electroswitch Series 24 CSR Control Switch Relays combine the function of a control switch with a remote controlled solenoid allowing one device to do both the manual and supervisory control function in the control of power circuit breakers. They eliminate the need to redesign substations for redundant separate relays when manual substations convert to supervisory control. Control Switch Relays provide manual or electric control switch operation by supervisory control. The Electroswitch Series 24 CSR looks, acts, and feels identical to a control switch.

-

Electrical Solutions

Electroswitch Series 24 CSR, Control Switch Relay

The Electroswitch Series 24 CSR Control Switch Relays combine the function of a control switch with a remote controlled solenoid allowing one device to do both the manual and supervisory control function in the control of power circuit breakers. They eliminate the need to redesign substations for redundant separate relays when manual substations convert to supervisory control. Control Switch Relays provide manual or electric control switch operation by supervisory control. The Electroswitch Series 24 CSR looks, acts, and feels identical to a control switch.

-

Electrical Solutions

Electroswitch Series 24 CSR/SD, SCADA Disable Control Switch Relay

The Electroswitch Series 24 CSR/SD, Control Switch Relay with SCADA Disable, operates like a standard CSR, allowing both SCADA and manual operation. Pushing in the handle disables remote operation leaving only Local/Manual operation possible. This action allows testing, and service to be performed safely. In addition, electrical connections (15 amp, 600 volt) are provided for the 2 N/C and N/O contacts at the terminal block deck located at the rear of the CSR/SD. These can be used to provide customer status indication.

-

Electrical Solutions

Electroswitch Series 24 CSR/SD, SCADA Disable Control Switch Relay

The Electroswitch Series 24 CSR/SD, Control Switch Relay with SCADA Disable, operates like a standard CSR, allowing both SCADA and manual operation. Pushing in the handle disables remote operation leaving only Local/Manual operation possible. This action allows testing, and service to be performed safely. In addition, electrical connections (15 amp, 600 volt) are provided for the 2 N/C and N/O contacts at the terminal block deck located at the rear of the CSR/SD. These can be used to provide customer status indication.

-

Electrical Solutions

Electroswitch Series 24 LOR, Lock-Out Relay

The Electroswitch Series 24 LOR, Lock-Out Relay, is the industry standard for safety and reliability, and plays a pivotal role in crucial utility, and industrial applications. The Series 24 LOR offers a selection of Manual Reset, Electric Reset or Self-Reset versions, and comes with optional lighted target nameplates to save on space and cost. The Series 24 LOR utility control switches comply with ANSI/IEEE 37.90, and ANSI/IEEE 37.90.01.

-

Electrical Solutions

Electroswitch Series 24 LOR, Lock-Out Relay

The Electroswitch Series 24 LOR, Lock-Out Relay, is the industry standard for safety and reliability, and plays a pivotal role in crucial utility, and industrial applications. The Series 24 LOR offers a selection of Manual Reset, Electric Reset or Self-Reset versions, and comes with optional lighted target nameplates to save on space and cost. The Series 24 LOR utility control switches comply with ANSI/IEEE 37.90, and ANSI/IEEE 37.90.01.

-

Electrical Solutions

Electroswitch Series 24 Model 24PC38D Breaker Control Switch

The Electroswitch Series 24 Model 24PC38D Breaker Control Switch with Lighted Nameplate provides local and remote SCADA annunciation of breaker trip coil failure. This series of control switches can be manually and remotely operated, are easy to use, require no special operator training, and can be wired to indicate any desired event. The Series 24 lighted nameplates are available with one, two, or three replaceable LEDs. These lighted nameplates can be used on all Series 24 Switches saving panel space, and reducing purchase and installation costs.

-

Electrical Solutions

Electroswitch Series 24 Model 24PC38D Breaker Control Switch

The Electroswitch Series 24 Model 24PC38D Breaker Control Switch with Lighted Nameplate provides local and remote SCADA annunciation of breaker trip coil failure. This series of control switches can be manually and remotely operated, are easy to use, require no special operator training, and can be wired to indicate any desired event. The Series 24 lighted nameplates are available with one, two, or three replaceable LEDs. These lighted nameplates can be used on all Series 24 Switches saving panel space, and reducing purchase and installation costs.

-

Electrical Solutions

Electroswitch Series 24 Rotary Control Switch

The Electroswitch Series 24 Rotary Instrument and Control Switches are the quality standard in the utility industry, satisfying some of the most stringent requirements in substation automation, power generation, transmission and power distribution systems. This control switch is designed to meet or exceed ANSI 37.90 requirements, and features low resistance, double-wiping contacts with self-cleaning silver contacts for years of reliable service. The Series 24 control switch is available with up to ten decks (20 poles), and allows for between 2 and 8 positions. These switches are rated at 30 amps @ 600 volts.

-

Electrical Solutions

Electroswitch Series 24 Rotary Control Switch

The Electroswitch Series 24 Rotary Instrument and Control Switches are the quality standard in the utility industry, satisfying some of the most stringent requirements in substation automation, power generation, transmission and power distribution systems. This control switch is designed to meet or exceed ANSI 37.90 requirements, and features low resistance, double-wiping contacts with self-cleaning silver contacts for years of reliable service. The Series 24 control switch is available with up to ten decks (20 poles), and allows for between 2 and 8 positions. These switches are rated at 30 amps @ 600 volts.

-

Electrical Solutions

Electroswitch Series 24 Smart LOR, Lock-Out Relay with Lighted Nameplate

The Electroswitch Series 24 Lighted LOR, Lock-Out Relay, with Lighted Nameplate is the industry standard for safety and reliability, and plays a pivotal role in crucial utility, and industrial applications. The Series 24 LOR offers a selection of Manual Reset, Electric Reset or Self-Reset versions, and comes with optional lighted target nameplates to save on space and cost. The Series 24 LOR utility control switches comply with ANSI/IEEE 37.90, and ANSI/IEEE 37.90.01.

-

Electrical Solutions

Electroswitch Series 24 Smart LOR, Lock-Out Relay with Lighted Nameplate

The Electroswitch Series 24 Lighted LOR, Lock-Out Relay, with Lighted Nameplate is the industry standard for safety and reliability, and plays a pivotal role in crucial utility, and industrial applications. The Series 24 LOR offers a selection of Manual Reset, Electric Reset or Self-Reset versions, and comes with optional lighted target nameplates to save on space and cost. The Series 24 LOR utility control switches comply with ANSI/IEEE 37.90, and ANSI/IEEE 37.90.01.

-

Electrical Solutions

Electroswitch Series 24 Smart Rotary Control Switch with Lighted Nameplate

The Electroswitch Series 24 Lighted Smart Rotary Control Switch with Lighted Nameplate provides local and remote SCADA annunciation of breaker trip coil failure. This series of control switches can be manually and remotely operated, are easy to use, require no special operator training, an can be wired to indicate any desired event. The Series 24 lighted nameplates are available with one, two, or three replaceable LEDs. These lighted nameplates can be used on all Series 24 Switches saving panel space, and reducing purchase and installation costs.

-

Electrical Solutions

Electroswitch Series 24 Smart Rotary Control Switch with Lighted Nameplate

The Electroswitch Series 24 Lighted Smart Rotary Control Switch with Lighted Nameplate provides local and remote SCADA annunciation of breaker trip coil failure. This series of control switches can be manually and remotely operated, are easy to use, require no special operator training, an can be wired to indicate any desired event. The Series 24 lighted nameplates are available with one, two, or three replaceable LEDs. These lighted nameplates can be used on all Series 24 Switches saving panel space, and reducing purchase and installation costs.

-

Counters/Timers

ISSC Kanson Electronics Model 1310 Din Rail Mount Industrial Solid State On Delay Timer

The ISSC Kanson Electronics Model 1310 is a control-on delay timer, built specifically for continuous duty operation.

The 1310 control-on delay timer is for electric utility applications capable of high voltage DC switching.

The 1310 industrial solid state on delay timer comes with Din-Rail mounted housing with finger-safe electrical connectors (IP20 rating), reinforced isolation for relays (sealed relays), and timed and instantaneous contacts.

Upon application of input voltage into the ISSC Kanson 1310 control-on delay timer, the time delay relay is ready to accept a control signal. When the control is applied, the time delay begins. At the end of the time delay, the output is energized and remains in that condition as long as either the control is applied or the input voltage remains. If the control is removed during the time delay, the output remains de-energized and the time delay is reset.

-

Counters/Timers

ISSC-Kanson Electronics Model 1071 Plug-in Industrial Solid State Timer

The ISSC-Kanson Electronics Model 1071 plug-in industrial solid state timer is a multi-range unit which is programmable for 8 different time ranges. The 1071 reduces inventory requirements by offering the time range capacity of eight separate timers in one unit. Input Power Actuates timing sequence, eliminating the need for a separate control circuit. Removing power automatically resets timing sequence. Input Is Compatible with both standard mechanical switches and solid state proximity sensors.

-

Counters/Timers

ISSC-Kanson Electronics Model 1105C Plug-in or DIN Panel Mount Digital Preset Counter

The ISSC-Kanson Electronics Model 1105C features two 2 input and 5 input functions and a large, 6 digit LCD display. Two input count speeds (30/sec or 5000/sec) can be used to eliminate noise. There are 7 output functions with SPDT relay or optional transistor output. Two power supply options are available, a wide range of 100 to 240 VAC and a 12 to 24VDC only version. A battery back-up maintains memory up to 7 years.

-

Counters/Timers

ISSC-Kanson Electronics Model 1248A Limit Style, Industrial Solid State Proximity Sensor / Speed Switch, Motion Detector

The ISSC-Kanson Electronics Model 1071 plug-in industrial solid state timer is a multi-range unit which is programmable for 8 different time ranges. The 1071 reduces inventory requirements by offering the time range capacity of eight separate timers in one unit. Input Power Actuates timing sequence, eliminating the need for a separate control circuit. Removing power automatically resets timing sequence. Input Is Compatible with both standard mechanical switches and solid state proximity sensors.

-

ITT Conoflow

ITT Conoflow FR95 Airpak Filter-Regulator, Aluminum Low Pressure Regulator

The ITT Conoflow FR95 Series Airpak® Filter-Regulator is used to provide clean, accurate air to instruments, valves, positioners, transducers, and other pneumatic control devices. The design provides high flow capability, durable materials of construction and bubble-tight shutoff. The FR95 low pressure regulator has a maximum supply pressure capability of 250 psig (1724 kPa) with control output settings of 0-25 psig, 0-35 psig, 0-60 psig, and 0-125 psig (0-172 kPa, 0-241 kPa, 0-414kPa, and 0-862 kPa). This light-weight filter-regulator boasts a high flow delivery rate and excellent droop characteristic. The FR95 regulator is offered with 1/4″ NPT inlet and outlet ports, two outlet gauge ports, all aluminum construction, and has a black anodized exterior for superior corrosion resistance.

-

ITT Conoflow

ITT Conoflow GFH45 Airpak Filter-Regulator, Brass Low Pressure Regulator

The ITT Conoflow GFH45 Series Airpak® Filter-Regulator is used to provide clean, accurate air to instruments, valves, positioners, transducers, and other pneumatic control devices. The design provides high flow capability, durable materials of construction and bubble-tight shutoff. The GFH45 low pressure regulator has a maximum supply pressure capability of 300 psig (2.07 MPa) with control output settings of 0-25 psig, 0-60 psig, and 0-125 psig (0-172 kPa, 0-414 kPa, and 0-862 kPa). This brass filter-regulator boasts a high flow delivery rate and excellent droop characteristic. Th GFH45 regulator is offered with 1/4″ NPT inlet and outlet ports, two outlet gauge ports, and brass construction.

The ITT Conoflow GFH45 Series Airpak® Filter-Regulator is used to provide clean, accurate air to instruments, valves, positioners, transducers, and other pneumatic control devices. The design provides high flow capability, durable materials of construction and bubble-tight shutoff. The GFH45 low pressure regulator has a maximum supply pressure capability of 300 psig (2.07 MPa) with control output settings of 0-25 psig, 0-60 psig, and 0-125 psig (0-172 kPa, 0-414 kPa, and 0-862 kPa). This brass filter-regulator boasts a high flow delivery rate and excellent droop characteristic. Th GFH45 regulator is offered with 1/4″ NPT inlet and outlet ports, two outlet gauge ports, and brass construction.

-

ITT Conoflow

ITT Conoflow GH04 Cushion Loading Regulator

The ITT Conoflow GH04 Cushion Loading Regulator is an all aluminum, light-weight, compact unit designed for industrial and commercial services requiring a constant, regulated air pressure. The GH04 is primarily used as a cushion loading device for piston actuators, but the high exhaust capabilities make it suitable for many other applications. This model offers versatility in line mounting and gauge mounting with 1/4″ NPT dual input and output connections. It is available with a 0-60 psi (0-414 kPa) regulated pressure range, Buna-N elastomers, and the controlling ball valve is Viton.

-

ITT Conoflow

ITT Conoflow GH10 Brass Manual Loading Regulator

The ITT Conoflow GH10 Manual Loading Regulator is a precision unit designed for use in laboratory environments, remote loading of pneumatic devices, speed changers, and other general purpose applications. This GH10 model has a brass bonnet.

-

ITT Conoflow

ITT Conoflow GH10 Brass Manual Loading Regulator with Aluminum Bonnet

The ITT Conoflow GH10 Manual Loading Regulator is a precision unit designed for use in laboratory environments, remote loading of pneumatic devices, speed changers, and other general purpose applications. This GH10 model has an aluminum bonnet.

-

ITT Conoflow

ITT Conoflow GH10 Manual Loading Regulator with 303 Stainless Steel or 316 Stainless Steel Internals

The ITT Conoflow GH10 Manual Loading Regulator is a precision unit designed for use in laboratory environments, remote loading of pneumatic devices, speed changers, and other general purpose applications. This GH10 model is available with either 303 stainless steel internals, or 316 stainless steel internals for applications in harsh environments.

-

ITT Conoflow

ITT Conoflow GH20 Brass Service Pressure Reducing Regulator

The ITT Conoflow GH20 Service Pressure Reducing Regulator is a rugged unit with flow capacities, and performance characteristics which allow it to operate in both instrument, and industrial applications. This GH20 model has a brass bonnet.

-

ITT Conoflow

ITT Conoflow GH20 Brass Service Pressure Reducing Regulator with Aluminum Bonnet

The ITT Conoflow GH20 Service Pressure Reducing Regulator is a rugged unit with flow capacities, and performance characteristics which allow it to operate in both instrument, and industrial applications. This GH20 model has an aluminum bonnet.

-

ITT Conoflow

ITT Conoflow GH20 Service Pressure Reducing Regulator with 303 Stainless Steel or 316 Stainless Steel Internals

The ITT Conoflow GH20 Service Pressure Reducing Regulator is a rugged unit with flow capacities, and performance characteristics which allow it to operate in both instrument, and industrial applications. This GH20 model is available with either 303 stainless steel internals, or 316 stainless steel internals for applications in harsh environments.

-

ITT Conoflow

ITT Conoflow GH20VT 316 Stainless Steel Vacuum Service Regulator

The ITT Conoflow GH20VT 316 Stainless Steel Vacuum Regulator is used to provide a regulated vacuum by accurately regulating the sub-atmospheric pressure of a vessel being evacuated. This series of vacuum service regulators is especially suited for laboratory work, and test stands for simulation of high altitude conditions.

-

ITT Conoflow

ITT Conoflow GH20VT Brass Vacuum Service Regulator

The ITT Conoflow GH20VT Brass Vacuum Regulator is used to provide a regulated vacuum by accurately regulating the sub-atmospheric pressure of a vessel being evacuated. This series of vacuum service regulators is especially suited for laboratory work, and test stands for simulation of high altitude conditions.

-

ITT Conoflow

ITT Conoflow GH21XT Fixed, Constant, Differential Pressure Regulator

The ITT Conoflow GH21XT Fixed Differential Pressure Regulator is used to maintain a constant pressure differential across a variable or fixed orfice, providing a constant, or fixed, flow rate regardless of variations in upstream or downstream pressure. Various configurations of this differential pressure regulator are available based on the needs of the application. The GH21XT maintains a fixed differential of approximately 3 psi (21 kPa) across the bonnet, and outlet connection. Adjustment of the flow rate is made downstream of the system. This model constant differential pressure regulator is normally used with a flow rate indicator having a built-in needle valve.

-

ITT Conoflow

ITT Conoflow GH30 Back Pressure Regulator

The ITT Conoflow GH30 Back Pressure Regulator is used to maintain a constant upstream pressure of gas, vapor or liquid. Designed for accurate regulation under low flow conditions, this model back pressure regulator is widely used for protection of analysis instrumentation, or as a relief valve in supply pressure lines to control devices. The GH30 back pressure regulator is available in a brass and aluminum combination, or all stainless steel construction. This model has a Buna-N diaphragm assembly as standard, and a Teflon / Buna-N / Teflon diaphragm assembly is used in the stainless steel models for corrosive services. Regulated pressure ranges for this back pressure regulator are 0-3 psi, 5 psi, 15 psi, 25 psi, 35 psi, 50 psi, and 125 psi (0-21 kPa, 35 kPa, 103 kPa, 241 kPa, 345 kPa, and 862 kPa).

-

ITT Conoflow

ITT Conoflow GH40 Brass Service Pressure Reducing Regulator

The ITT Conoflow GH40 Service Pressure Reducing Regulator is for applications where positive shutoff, and minimum air consumption are required. These rugged pressure regulators have flow capacities, and performance characteristics which allow them to operate in both instrument, and industrial applications. This model service pressure reducing regulator has a Buna-N diaphragm assembly, and regulated output pressure ranges of 0-25 psi, 60 psi, and 125 psi (0-172 kPa, 414 kPa, and 862 kPa).

-

ITT Conoflow

ITT Conoflow GH40 Brass Service Pressure Reducing Regulator with Aluminum Bonnet

The ITT Conoflow GH40 Service Pressure Reducing Regulator is for applications where positive shutoff, and minimum air consumption are required. These rugged pressure regulators have flow capacities, and performance characteristics which allow them to operate in both instrument, and industrial applications. This model service pressure reducing regulator has an aluminum bonnet, a Buna-N diaphragm assembly, and regulated output pressure ranges of 0-25 psi, 60 psi, and 125 psi (0-172 kPa, 414 kPa, and 862 kPa).

-

ITT Conoflow

ITT Conoflow GH40 Service Pressure Reducing Regulator with 302 Stainless Steel or 316 Stainless Steel Internals

The ITT Conoflow GH40 Service Pressure Reducing Regulators are for applications where positive shutoff, and minimum air consumption are required. These rugged pressure regulators have flow capacities, and performance characteristics which allow them to operate in both instrument, and industrial applications. These models have either 302 stainless steel internals, or 316 stainless steel internals, and are equipped with Teflon / Buna-N / Teflon diaphragm assembly.

-

ITT Conoflow

ITT Conoflow GH40VT 316 Stainless Steel Vacuum Service Regulator

The ITT Conoflow GH40VT 316 Stainless Steel Vacuum Regulator is used to provide a regulated vacuum by accurately regulating the sub-atmospheric pressure of a vessel being evacuated. This series of vacuum service regulators is especially suited for laboratory work, and test stands for simulation of high altitude conditions.

-

ITT Conoflow

ITT Conoflow GH40VT Brass Vacuum Service Regulator

The ITT Conoflow GH40VT Brass Vacuum Regulator is used to provide a regulated vacuum by accurately regulating the sub-atmospheric pressure of a vessel being evacuated. This series of vacuum service regulators is especially suited for laboratory work, and test stands for simulation of high altitude conditions.

-

ITT Conoflow

ITT Conoflow GVB11, GVB12 Snap-Acting Relays

The ITT Conoflow GVB11 and GVB12 Snap-Acting Relays are lightweight, compact, and are easily piped and mounted. These snap-acting relays change ports to switch or lock in secondary air source when the main supply pressure fails below a predetermined set point. In the event of supply or pilot pressure failure, the positive action relay with one common, and two inlet or outlet ports will automatically switch from main to auxiliary supply pressure, lock an actuator in its last position, extend or retract an actuator stem, and divert flow or pressure from one device to another. The GVB11 and GVB12 snap-acting relays have an integral pilot which eliminates the extra piping, and connections required with other lock-up valves.

-

ITT Conoflow

ITT Conoflow HP500 High Pressure Reducing Regulator, High Purity Diaphragm Type

The ITT Conoflow HP500 High Pressure Reducing Regulator is a self-contained, diaphragm sensing high purity regulator. A broad offering of construction materials, and five control pressure ranges allow for applications that include regulating specialty gasses, gas chromatography, research labos, and the regulation of corrosive and noncorrosive gasses and liquids. This high purity pressure regulator is designed to accurately control pressure ranges of 4-25 psig, 4-50 psig, 5-100 psig, 6-250 psig, and 10-500 psig (0-0.173 MPa, 0-0.345 MPa, 0-0.690 MPa, 0-1.73 MPa, and 0-3.45 MPa). The HP500 has 1/4″ NPT inlet and outlet connections. Gauge ports are optional. To suit high purity applications, Vacuseal, VCR, and Ultra Seal welded fittings are available. Adjustments within each range are made with a standard large handwheel. A wrench style knob with a locking device, and a T bar handle are optional.

-

Flow Meters Indicators

Jacoby-Tarbox 90° Flanged Bulls-Eye Sight Flow Indicators, ASME Class 150 & 300

The Jacoby-Tarbox line of ASME rated high pressure threaded bulls-eye sight flow indicators are engineered per the design criteria of ASME B31.1 & B31.3, Power and Process Piping Codes, incorporating the listed ASTM materials for all metals in the unit construction.

-

Flow Meters Indicators

Jacoby-Tarbox Flanged Bulls-Eye Full-View Sight Flow Indicators, ASME Class 150

The Jacoby-Tarbox line of flanged bulls-eye sight flow indicators have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating all ASTM listed materials for the pressure retaining components: bodies, fasteners, and retainers. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure/temperature ratings.

-

Flow Meters Indicators

Jacoby-Tarbox High Pressure Flanged Bulls-Eye Sight Flow Indicators, ASME Class 300, 600, 900 & 1500

The Jacoby-Tarbox line of ASME rated high pressure flanged bulls-eye sight flow indicators are engineered per the design criteria of ASME B31.1 & B31.3, Power and Process Piping Codes, incorporating the listed ASTM materials for all metals in the unit construction.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

acoby-Tarbox ASME flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.

-

Flow Meters Indicators

Jacoby-Tarbox High Pressure Threaded Bulls-Eye Sight Flow Indicators, ASME Class 300, 600, 900 & 1500

The Jacoby-Tarbox line of threaded bulls-eye sight flow indicators have been precisely engineered per the design criteria of ASME to provide a full ASME rated for flow observation and indication. Threaded bullseye sight flows have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating only ASTM listed metals in the unit’s construction. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure / temperature ratings.

-

Flow Meters Indicators

Jacoby-Tarbox Hy-Sight Full View Hygienic Sight Flow Indicator

Jacoby-Tarbox Hy-Sight Full View hygienic sight flow indicators are designed and manufactured to provide an uninterrupted window for observation of the process flow in high purity applications. The Hy-Sight Full View hygienic sight flow indicator encompasses all of the transition and sealing advances of the Hy-Sight and adds 360° viewing plus customizable overall lengths. Hy-Sight Full View’s four window design is the largest of any slim, low-profile sight flow indicator, providing maximum process visibility and superior views in any orientation, and is available with customizable lengths.

-

Flow Meters Indicators

Jacoby-Tarbox Hy-Sight Hygienic Sight Flow Indicator

Jacoby-Tarbox Hy-Sight hygienic sight flow indicators are designed and manufactured to provide an uninterrupted window for observation of the process flow in high purity applications. The Hy-Sight hygienic sight flow indicators feature the cleanest glass to metal transition point, resulting from precision-bore borosilicate glass, positive stop design controlling compression of tightened tolerance EHEDG inspired O-ring capture. The Hy-Sight’s four window design is the largest of any slim, low-profile sight flow indicator, providing maximum process visibility and superior views in any orientation.

-

Flow Meters Indicators

Jacoby-Tarbox Threaded Bulls-Eye Full-View Sight Flow Indicators, SA ASME Class 150 Models

Jacoby-Tarbox’s full ASME rated line of flanged bulls-eye sight flows have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating all ASTM listed materials for the pressure retaining components: bodies, fasteners, and retainers. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure / temperature ratings.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

Jacoby-Tarbox ASME Class 150 flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.

-

Flow Meters Indicators

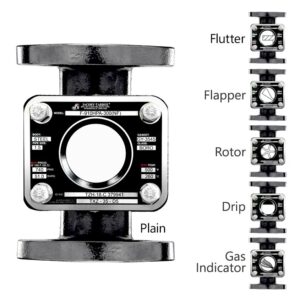

Jacoby-Tarbox Threaded Bulls-Eye Full-View Sight Flow Indicators, ST 150 psig Models