Flow Meters Indicators

Showing all 15 results

-

AW-Lake

AW-Lake Basic Inline Liquid Variable Area Flow Meter

The AW-Lake Basic Inline Liquid Variable Area Flow Meter is ideal for monitoring pump performance and oil or water flows through hydraulic circuits and cooling systems. Often referred to as rotameters, AW-Lake’s Basic variable area flow meters are a low cost alternative to other flow meter types and are available in numerous materials of construction, including aluminum, brass and stainless steel to meet system and media requirements. The superior design of this inline flow meter makes it not only weather-proof for outdoor environments and wash-downs, but also reliable with maintenance-free performance.

-

AW-Lake

AW-Lake Clamp-On Ultrasonic Transit Time Flow Meter

The AW-Lake Clamp-On Ultrasonic Transit Time Flow Meter fastens on the outside of vertical or horizontal pipes ranging in size from ½” through 48”. Housed in a water-and dust-tight NEMA4X polycarbonate enclosure, the Clamp-On Ultrasonic Flow Meters are compatible with a range of metal and plastic pipe materials and corrosive liquids that would damage standard flow meters. As a result, the non-intrusive, clamp-on ultrasonic sensors feature enhanced flow measurement with no pressure drop in a range of applications such as food or chemical processing plants, oil refineries, and more.

-

AW-Lake

AW-Lake Classic Series TCM TRICOR Coriolis Mass Flow Meters

The AW-Lake TCM CLASSIC Series of Coriolis Mass Flow Meters meets general industrial requirements with out-of-the-box ease of use. The lower cost and lower performance specs of the TCM Classic Series meets broader application needs. The TRICOR Coriolis Mass Flow Meters from TASI Flow are absolutely reliable and robust sensors in a variety of processes, performing multiple measurements simultaneously with customizable process parameters and multiple communication languages. The production team mechanically balances every meter, assuring the dual tubes are dynamically aligned and in perfect balance before flow begins. The unique design and cutting edge manufacturing procedures ensure a meter with the highest resistance to external influences.

-

AW-Lake

AW-Lake FlowStat Turbine Flow Sensor, Paddle Wheel Flow Meters

The AW-Lake FlowStat Paddle Wheel Flow Meters are used to monitor various fluids. This turbine flow rate sensor can be connected directly to analog acquisition cards, chart recorders or other monitoring instruments without external signal conditioning. The FlowStat flow rate meter integrates rugged tangential turbine technology with a precision digital to analog conversion circuit hermetically encapsulated within the body of the meter.

-

AW-Lake

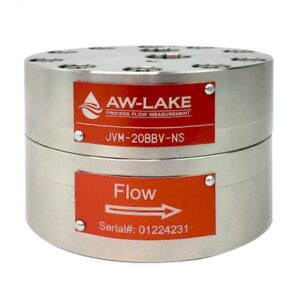

AW-Lake JV-BB Next-Gen Positive Displacement Gear Meter Flow Meter

The AW-Lake JV-BB Positive Displacement Flow Meter is part of the Next-Generation line of Gear Meters. These high performance flow meters have tighter machining tolerances, higher resolution, higher pressure rating, and improved accuracy over their predecessor, the JV-KG flow meter. As a result, operational costs are reduced. This flow meter maintains high accuracy and repeatability, despite changing viscosity conditions, up to ±0.25% accuracy with select sensors.

-

AW-Lake

AW-Lake TCMH 0450 High Pressure Hydrogen Coriolis Mass Flow Meters

The AW-Lake TCMH 0450 High Pressure Hydrogen Coriolis Mass Flow Meter is the world’s first MI-002 / OIML137 certified Coriolis flow meter for hydrogen dispensing and is offered in three pressure ratings: 6,000 psi, 10,000 psi and 15,200 psi. The U-shape tubes are made from Sandvik® Alloy HP 160, chosen to eliminate hydrogen embrittlement, such as in Hydrogen fueling stations.

-

Dwyer

Dwyer Series RM Rate-Master Polycarbonate Flowmeters

The Dwyer Series RM Rate-Master Flowmeters are a line of general use, direct reading precision flowmeters suitable for both gas and liquid applications. The RM Rate-Master® Polycarbonate Variable Area Flowmeter Series consists of 2″, 5″ and 10″ scales that can be panel or surface mounted with optional precision metering valves. The Rate-Master flowmeter bodies can be instantly interchanged within the same series scale size, allowing the piping to remain undisturbed, interchangeability of the ranges, and easy cleaning.

The Dwyer Series RM Rate-Master® Polycarbonate Flowmeters are available with optional adjustable pointer flags which provide a quick visual reference to a required flow level. Made of clear plastic, the pointer flags snap into place inside the bezel and slide to the desired level. The RM Rate-Master Polycarbonate Flowmeters are also available with an optional NIST traceable calibration certificate.

-

Flow Meters Indicators

Jacoby-Tarbox 90° Flanged Bulls-Eye Sight Flow Indicators, ASME Class 150 & 300

The Jacoby-Tarbox line of ASME rated high pressure threaded bulls-eye sight flow indicators are engineered per the design criteria of ASME B31.1 & B31.3, Power and Process Piping Codes, incorporating the listed ASTM materials for all metals in the unit construction.

-

Flow Meters Indicators

Jacoby-Tarbox Flanged Bulls-Eye Full-View Sight Flow Indicators, ASME Class 150

The Jacoby-Tarbox line of flanged bulls-eye sight flow indicators have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating all ASTM listed materials for the pressure retaining components: bodies, fasteners, and retainers. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure/temperature ratings.

-

Flow Meters Indicators

Jacoby-Tarbox High Pressure Flanged Bulls-Eye Sight Flow Indicators, ASME Class 300, 600, 900 & 1500

The Jacoby-Tarbox line of ASME rated high pressure flanged bulls-eye sight flow indicators are engineered per the design criteria of ASME B31.1 & B31.3, Power and Process Piping Codes, incorporating the listed ASTM materials for all metals in the unit construction.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

acoby-Tarbox ASME flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.

-

Flow Meters Indicators

Jacoby-Tarbox High Pressure Threaded Bulls-Eye Sight Flow Indicators, ASME Class 300, 600, 900 & 1500

The Jacoby-Tarbox line of threaded bulls-eye sight flow indicators have been precisely engineered per the design criteria of ASME to provide a full ASME rated for flow observation and indication. Threaded bullseye sight flows have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating only ASTM listed metals in the unit’s construction. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure / temperature ratings.

-

Flow Meters Indicators

Jacoby-Tarbox Hy-Sight Full View Hygienic Sight Flow Indicator

Jacoby-Tarbox Hy-Sight Full View hygienic sight flow indicators are designed and manufactured to provide an uninterrupted window for observation of the process flow in high purity applications. The Hy-Sight Full View hygienic sight flow indicator encompasses all of the transition and sealing advances of the Hy-Sight and adds 360° viewing plus customizable overall lengths. Hy-Sight Full View’s four window design is the largest of any slim, low-profile sight flow indicator, providing maximum process visibility and superior views in any orientation, and is available with customizable lengths.

-

Flow Meters Indicators

Jacoby-Tarbox Hy-Sight Hygienic Sight Flow Indicator

Jacoby-Tarbox Hy-Sight hygienic sight flow indicators are designed and manufactured to provide an uninterrupted window for observation of the process flow in high purity applications. The Hy-Sight hygienic sight flow indicators feature the cleanest glass to metal transition point, resulting from precision-bore borosilicate glass, positive stop design controlling compression of tightened tolerance EHEDG inspired O-ring capture. The Hy-Sight’s four window design is the largest of any slim, low-profile sight flow indicator, providing maximum process visibility and superior views in any orientation.

-

Flow Meters Indicators

Jacoby-Tarbox Threaded Bulls-Eye Full-View Sight Flow Indicators, SA ASME Class 150 Models

Jacoby-Tarbox’s full ASME rated line of flanged bulls-eye sight flows have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating all ASTM listed materials for the pressure retaining components: bodies, fasteners, and retainers. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure / temperature ratings.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

Jacoby-Tarbox ASME Class 150 flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.

-

Flow Meters Indicators

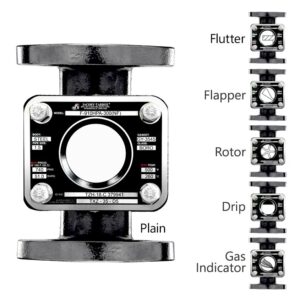

Jacoby-Tarbox Threaded Bulls-Eye Full-View Sight Flow Indicators, ST 150 psig Models

Jacoby-Tarbox’s full line of threaded bulls-eye sight flow indicators have been precisely engineered per the design criteria of ASME to provide either a nominal 150 psig rated unit or a full ASME rated for flow observation and indication. Threaded bullseye sight flows have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating only ASTM listed metals in the unit’s construction. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure/temperature ratings.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

Jacoby-Tarbox ASME flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.