Level Gauges

Showing all 12 results

-

Apollo

Apollo Valves 20-100, 20-200, 20-300 Series Bronze Liquid Level Gauges, Water Gauges

The Apollo® 20 Series Bronze Liquid Level Gauges, or water gauges, meet ASME design requirements, and are for use on all types of liquid level verification. These liquid level gauge sets are available in many variations including heavy bronze body patterns for higher service ratings, and with aluminum or plastic composite handles. An Apollo® standard liquid level gauge set includes top and bottom valves, sight glass, coated steel guard rods, and a 1/4″ drain valve. The Apollo® 20-100 series fits pipe sizes 3/8″ or 1/2″, the 20-200 series fits pipe sizes 3/8″ through 3/4″, and the 20-300 series is available in 1/2″ or 3/4″ pipe sizes. Made in the USA.

-

Jerguson

Jerguson 125 Series Valve Sets for Tubular Glass Gages, Tubular Glass Level Gages, Liquid Level Valves for Tubular Glass Gages

These tubular glass gage cocks represent years of experience in the manufacture of gage cocks and offer a variety of types and connections to suit all requirements.

The Jerguson No. 125 Standard valve for tubular glass gages has a standard straight-through flow design featuring a durable cast aluminum wheel. Connections of 1/2″ or 3/4″ NPT are available for attaching the valve to the vessel. Consider this model to replace the 12-T.

Maximum working pressure dependent on length and resultant pressure rating of glass.

-

Jerguson

Jerguson 136 Series Tubular Glass & Valve Sets, Tubular Glass Level Gages, Liquid Level Valves for Tubular Glass Gages

The Jerguson No. 136 Standard valve for tubular glass gages has a standard straight-through flow design featuring a durable cast aluminum wheel. Connections of 1/2″ or 3/4″ NPT are available for attaching the valve to the vessel.

-

Jerguson

Jerguson 140 Series Liquid Level Valves, Integral Bonnet Safety Ballcheck Valves

Jerguson No. 140 Series Valves provide long trouble-free service at economical cost. Their design incorporates such quality features as stainless steel stems and ballchecks.

A comprehensive selection of connections provides the versatility required to conform to most piping requirements. Optional features permit a high degree of customization to meet very specific demands. The No. 143 has a straight pattern with non-union gage connection, the No. 144 has a straight pattern with union gage connection, the No. 146 has an offset pattern with non-union gage connection, and the No. 147 is an offset pattern with union gage connection.

-

Jerguson

Jerguson 56 Series Tubular Glass & Valve Sets, Tubular Glass Level Gages, Liquid Level Valves for Tubular Glass Gages

The Jerguson No. 56 Standard valve for tubular glass gages has a standard straight-through flow design featuring a durable cast aluminum wheel. Connections of 1/2″ or 3/4″ NPT are available for attaching the valve to the vessel.

-

Jerguson

Jerguson Series 20 Liquid Level Gages, Reflex R-20 and Transparent T-20, Armored Flat Glass Gages

The Jerguson Series 20 liquid level gage is the most commonly produced covering 80-85% of the applications encountered. The Series 20 armored glass gage features a recessed gasket surface, and shrouded covers. A recessed gasket surface provides positive location of the seal gasket during both assembly and field repair. This makes it possible to repair the gage while mounted to the vessel. The recessed gasket surface contains the gasket to prevent lateral movement which could lead to a gasket blow-out (as with competitive gages). All Jerguson armored glass gages are hydrostatically tested at 1 1/2 times the design pressure rating at 100°F (38°C) prior to shipment.

-

Jerguson

Jerguson Series 300L Liquid Level Gages, Reflex R-300L and Transparent T-300L, Armored Flat Glass Gages, ANSI 300

The Jerguson Series 300L liquid level gages are lower cost with increased visible ranges. The series 300L provides a more visible range per gage section at an economical price. This glass gage series uses the proprietary Jerguson 25mm glass, which is thinner, narrower, and longer than traditional gage glass. The Series 300L features a recessed gasket surface, bar-stock non-shrouded covers, and ASTM grade bolting. Due to the length of each gage section this model is not recommended for high pressure steam service. All Jerguson armored flat glass gages are hydrostatically tested prior to shipment at 1 1/2 times the design pressure rating at 100°F (38°C).

-

Jerguson

Jerguson Series 32 Liquid Level Gages, Reflex R-32 and Transparent T-32, Armored Flat Glass Gages

The Jerguson Series 32 liquid level gage looks very similar to a Series 20, with the exception that the Series 32 armored glass gage features recessed mid-span supports or tie-bars to allow for increased pressure ratings. This is very important as other brands do not recess their mid-span support which causes a blind spot in the vision. A recessed gasket surface provides positive location of the seal gasket during both assembly and field repair and also makes it possible to repair a Jerguson gage while it is mounted to the vessel. The recessed gasket surface is also an important safety feature in the fact that it contains the gasket and helps prevent lateral movement which could lead to a gasket blow-out (as with competitive gages.)

-

Jerguson

Jerguson Series 40 Heavy Duty Liquid Level Gages, Reflex R-40 and Transparent T-40, Armored Flat Glass Gages

The Jerguson Series 40 liquid level gage is used in heavy duty, high pressure process applications of 4,000 psi, or saturated steam applications requiring a 1,500 WSP rating. Jerguson Series 40 armored flat glass gages are simple, rugged instruments engineered to provide accurate liquid level readings for the life of the vessel they are installed. All liquid level flat glass gages are hydrostatically tested by Jerguson prior to shipment at 1 1/2 times the design pressure rating at 100°F (38°C).

-

Jerguson

Jerguson Series 51 High Pressure Liquid Level Gages, Transparent T-51, Armored Flat Glass Gages

The Jerguson Series 51 liquid level gage is a specially designed instrument capable of withstanding high pressures. The one-piece chamber of the Series 51 armored flat glass gage is machined out of solid bar stock carbon steel or stainless steel as specified. It is drilled lengthwise and crosswise at each port leaving tie-bars in between to resist deflection under pressure. The Viton O-rings that seal each port are unaffected by most liquids that cause deterioration in rubber. The O-rings are seated in recessed circular channels to assure proper seating action.

-

Jerguson

Jerguson Series L10 Large Chamber Liquid Level Gages for Boiling / Flashing Liquids, Reflex and Transparent Armored Flat Glass Gages

The Jerguson Series L10 large chamber liquid level gages are designed to give an accurate liquid level reading of liquids that have a tendency to surge or boil. These armored glass gages are highly effective in reducing the boiling effects of entrained gas being released under low pressure. They are effective at eliminating level fluctuations that occur in standard gages with small chambers when boiling / flashing vapors try to rise to the surface. Jerguson Series L 10 large chamber armored glass gages are available in reflex or transparent design. The liquid chamber is constructed of heavy tubing, carefully slotted, and machined to provide plane seats for the gaskets and glass assemblies. Covers are steel secured with specially designed steel bolts.

-

Jerguson

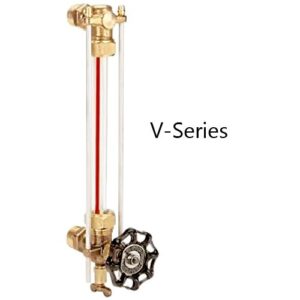

Jerguson V-Series Bronze Tubular Glass & Valve Sets, Tubular Glass Level Gages, Liquid Level Valves for Tubular Glass Gages

The Jerguson V-Series bronze gage valves feature VA & VC Automatic and VB & VE Non-Automatic glass gage valves. The VA Automatic series comes complete with corrosive-resistant ballchecks for automatic closure in the event of glass breakage. The VB Non-Automatic series is similar to the VA series except ballchecks are not standard, thus making operation non-automatic. The VC Automatic series conforms to ASME power-boiler code requirements and feature stainless steel ballchecks in both upper and lower units, thus providing automatic closure in the event of glass breakage. The VE Non-Automatic series is nearly identical in every aspect to the above models, except for the non-automatic design and ballchecks are not included.