Pressure guages

Showing all 70 results

-

Pressure guages

Ashcroft 1008S Stainless Steel Pressure Gauge

The Ashcroft® 40mm, 50mm, 63mm, 100mm 1008S pressure gauges are an excellent solution for pressure measurement in harsh environments. These gauges offer exceptional quality and reliability in an all stainless steel pressure gauge. The sealed case protects from ambient conditions and includes features enhancing product performance and safety. The 40 / 50mm gauges are ideal for limited space installations.

-

Dwyer

Dwyer Series 2000 Magnehelic Differential Pressure Gages

The Dwyer Series 2000 Magnehelic Differential Pressure Gages is selected for a versatile low differential pressure gage with a wide choice of 81 models and 27 options to choose from. Using Dwyer’s simple, frictionless Magnehelic® gage movement, it quickly indicates air or non-corrosive gas pressures – either positive, negative (vacuum) or differential. The design resists shock, vibration, over-pressures and is weatherproof to IP67.

The Dwyer Series 2000-HA High Accuracy Magnehelic Differential Pressure Gages are twice as accurate as the standard Magnehelic® gages. The well-engineered high accuracy Magnehelic® gage offers a mirrored overlay as standard in order to eliminate any parallax error when taking measurements. A six point calibration certificate is included with each high accuracy model. The rugged IP67 casing helps fully protect against dust and water ingress. The redesigned corrosion resistant brushed 304 stainless steel bezel option offers a clean tapered design, yet minimizes the possibility of any dust accumulation on the edges.

-

Dwyer

Dwyer Series 4000 Capsuhelic Differential Pressure Gages

The Dwyer Series 4000 Capsuhelic Differential Pressure Gages are designed to give fast, accurate indication of differential pressures. The Capsuhelic® Differential Pressure Gage may be used as a readout device when measuring flowing fluids, pressure drop across filters, liquid levels in storage tanks and many other applications involving pressure, vacuum or differential pressure. The pressure being measured is held within a capsule which is an integral part of the gage. This containment of the pressure permits the use of the gage on system pressures of up to 500 psig, even when differentials to be read are less than 0.1 in w.c.

The Dwyer Series 4000 Capsuhelic Differential Pressure Gages may be used with hydrogen where pressures are less than 35 psi, and should be ordered with a Buna-N diaphragm. The Series 4000 Capsuhelic gages are available with optional forged brass housing for water or water based fluids, adjustable signal flags, NIST traceable calibration certificate, and red, green, mirrored or combination scale overlays.

-

Pressure guages

Weksler EA1 HVAC Contractor Pressure Gauge

The Weksler EA1 HVAC Contractor Pressure Gauges are suitable for steam, water, oil, gas, air measurement, or any medium not corrosive to copper alloys due to its soft soldered phosphor bronze tube with brass socket.

The Weksler Contractor Pressure Gauges come with 4 1/2″ diameter corrosion resistant stainless steel case and ring, white dial with bold black graduations and figures for easy readability.

The Weksler EA1 HVAC Contractor Pressure Gauge has a balanced black pointer with a zero adjusting screw in the face of the instrument.

-

Pressure guages

Weksler Model UA20 Utility Pressure Gauge

The Weksler Model UA20 Utility Pressure Gauge is an inexpensive gauge for the broad commercial and industrial market. The Weksler Utility Pressure Gauge provides 3-2-3% accuracy for measuring water, oil, gas, or any medium not corrosive to brass or phosphor bronze.

The Weksler Model UA20 Utility Pressure Gauge is available with dual scale dials. The inner scale of bar/kPa is in blue while the outer scale of psi is in black, with both on a white background for easy readability.

-

Pressure guages

Wika 111.10 Utility Pressure Gauge

The WIKA® 111.10 commercial utility pressure gauge is designed for long and reliable service under rugged conditions. Typical applications are for pumps, hydraulic and pneumatic systems, compressors, as a contractor’s gauge and for applications where the media does not corrode brass.

-

Pressure guages

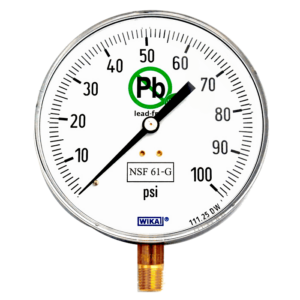

Wika 111.10DW Lead-Free Economy Pressure Gauge

The WIKA® 111.10DW bourdon tube pressure gauge is lead-free as part of the Drinking Water (DW) series of products for applications where water is anticipated to be used for human consumption.

-

Pressure guages

Wika 111.10R Commercial Refrigeration Pressure Gauge

The WIKA® 111.10R commercial refrigeration pressure gauge is ideal for compressed air systems, and refrigerator test manifolds. The gauge comes with a durable red or blue steel case and silicone dampened movement.

-

Pressure guages

Wika 111.10SP Sprinkler Pressure Gauge

The WIKA® 111.10SP 4″ gauge is specfically designed for fire sprinkler service. This gauge is UL and FM approved for fire sprinkler service and have a standard accuracy of ±3/2/3% of span.

-

Pressure guages

Wika 111.11 Compressed Gas Regulator Pressure Gauge

The WIKA® 111.11 commercial gauge is designed for use with compressed gases, such as those used in the welding industry. The bourdon tube for pressure ranges 800 psi and below has a low copper content making it safe for use with acetylene. The gauge is cleaned to ASME B40.100 Level IV, and is safe for use with oxygen.

-

Pressure guages

Wika 111.11PM Standard Panel Mount Pressure Gauge

The WIKA® 111.11PM is designed for a 2 1/2″ u-clamp panel mounting and features low friction SWISS movement to ensure a long, reliable service life.

-

Pressure guages

Wika 111.11RF Refrigeration Pressure Gauge

The WIKA® 111.11RF refrigeration gauge is designed as replacement gauges on refrigerant test manifolds. This gauge has a special movement design to eliminate flutter, making the gauge easy to read.

-

Pressure guages

Wika 111.12 Utility Pressure Gauge

The WIKA® 111.12 commercial utilty pressure gauge is available in a variety of sizes, mounting styles and configurations. It is suitable for tough applications including regulators, medical, pneumatic controllers, compressors, valve positioners and pumps.

-

Pressure guages

Wika 111.12DW Lead-Free Economy Pressure Gauge

The WIKA® 111.12DW bourdon tube pressure gauge is lead-free as part of the Drinking Water (DW) series of products for applications where water is anticipated to be used for human consumption.

-

Pressure guages

Wika 111.16, 111.26 Metric Panel Mount Pressure Gauge with Integrated Flange

The WIKA® 111.16 and 111.26 commercial panel mount gauge has an integrated panel mount flange. This model is often used in pneumatics and HVAC applications

-

Pressure guages

Wika 111.16PM Standard Panel Mount Pressure Gauge

The WIKA® 111.16PM commercial gauge is designed for u-clamp panel mounting. This model features a black ABS case and low friction Swiss movement to insure a long, reliable service life. The 111.16PM design fits into US size panel cut-outs.

-

Pressure guages

Wika 111.25CT Contractor Pressure Gauge

The WIKA® 111.25CT 4 1/2″ gauge is specifically designed for the HVAC market as a contractor’s gauge. This gauge features a stainless steel case, brass wetted parts, and adjustable pointer. Contractor’s gauges are designed for static applications and may not be well-suited to high vibration and pulsation applications.

-

Pressure guages

Wika 111.25DW Lead-Free Contractor Pressure Gauge

The WIKA® 111.25DW a lead-free drinking water contractor pressure gauge. This model is NSF/ANSI 61 listed and certified to NSF/ANSI 372. The gauge conforms to the lead content requirements for lead-free plumbing as defined by the US Safe Drinking Water Act.

-

Pressure guages

Wika 113.13 Hydraulic Pressure Gauge

The WIKA® 113.13 hydraulic commercial pressure gauge is ideal for OEM and general industrial applications requiring an economical, liquid-filled pressure gauge. The glycerine liquid fill dampens the bourdon tube and reduces wear of the movement, extending gauge life.

-

Pressure guages

Wika 113.53 Stainless Steel Case Pressure Gauge

The WIKA® 113.53 stainless steel case commercial pressure gauge features a 1 1/2″ dial size. The glycerine fill dampens and lubricates the gauge internals, extending the life of the gauge in applications with high dynamic pressure pulsations and vibrations.

-

Pressure guages

Wika 131.11 Stainless Steel Pressure Gauge

The WIKA® 131.11 stainless steel industrial pressure gauge is the best choice when installation space is limited, and stainless steel wetted parts are needed. The stainless steel construction makes this gauge ideal for harsh environments.

-

Pressure guages

Wika 132.53, 133.53 Stainless Steel Pressure Gauges

The WIKA® 132.53 and 133.53 stainless steel industrial pressure gauges are resistant to corrosive media and environments. They feature 316 SS wetted parts, series 300 SS case and movement, and a welded case-to-socket connection. Designed for static applications, these gauges may not be well-suited for high vibration and pulsation applications.

-

Pressure guages

Wika 211.11, 231.11 ‘Boiler Gauge’ Pressure Gauge

The WIKA® 211.11 10″ industrial Boiler Gauge pressure gauge is ideal for boiler room service or applications where its large dial size makes it easier to read from a distance. This gauge feature a black-painted steel case and a ±1.0% accuracy.

-

Pressure guages

Wika 212.20 Severe Service Industrial Pressure Gauge

The WIKA® 212.20 6″ pressure gauge is designed for severe industrial service. The large dial size makes it ideal for applications which require reading from a distance.

-

Pressure guages

Wika 212.25 Process Pressure Gauge with Hinged Ring

The WIKA® 212.25 process pressure gauge features a solid-front aluminum case with hinged ring for easy access to the adjustable pointer. This gauge is supplied with three threaded bolts in the back of the case which line up with existing standard panel hole patterns.

-

Pressure guages

Wika 212.34, 213.34 XSEL™ Process Pressure Gauges

The WIKA® 212.34 and 213.34 XSEL™ process pressure gauges are specifically designed for the chemical and petroleum processing industries. They are engineered to deliver years of accurate service, while withstanding vibration, corrosive media, corrosive environments and a wide range of temperature extremes.

-

Pressure guages

Wika 212.40PM, 213.40PM ‘Paper Machine’ Panel Mount Pressure Gauges

The WIKA® 213.40PM and 21340PM panel mount industrial pressure gauges are designed to fit existing paper machine panels. Each gauge is hermetically sealed to prevent moisture from entering during washdown. This model is liquid fillable for high vibration or pulsation applications. The oversized polished stainless steel front flange allows for an easy retrofit installation.

-

Pressure guages

WIKA 212.53, 213.53 STAINLESS STEEL CASE PRESSURE GAUGES

The WIKA® 212.53 and 213.53 industrial pressure gauges feature a stainless steel case for protection in harsh environments. The o-ring seal around the connection makes this gauge field fillable for high vibration and pulsation applications.

-

Pressure guages

Wika 212.54, 213.54 Heavy-Duty Stainless Steel Case Pressure Gauges

The WIKA® 212.54 and 213.54 heavy-duty industrial pressure gauges feature a stainless steel case, and are available in ranges up to 10,000 psi. The industrial grade Swiss movement assures repeatable accuracy and long service life in industrial environments.

-

Pressure guages

Wika 213.40 Brass Hydraulic Pressure Gauge

-

Pressure guages

Wika 213.53DW Lead-Free Stainless Steel Case Pressure Gauges

The WIKA® 213.53DW lead-free stainless steel case pressure gauge is intended for applications in which products musst comply with the 2014 US Safe Drinking Act and NSF 61/372. This gauge is for adverse service conditions where pulsation or vibration exist.

-

Pressure guages

Wika 232.25 Panel Mount Process Pressure Gauge with Hinged Ring

The WIKA® 232.25 process pressure gauge has a glass covered hinged ring to easily access the adjustable pointer. This model is designed for panel mounting, and is well-suited for installations in process panel and control applications. It also features 316 SS wetted parts, and a one-piece aluminum solid-front safety case design.

-

Pressure guages

Wika 232.30 & 233.30 Stainless Steel Pressure Gauge

The WIKA 232.30 & 233.30 stainless steel pressure gauge has a solid-front, blow-out back safety case.

This industrial gauge is an ideal choice for process, chemical, petrochemical, oil exploration, oil production, power generation, and other applications which demand a reliable pressure gauge.

The Wika 232.30 & 233.30 stainless steel pressure gauge meets API RP 551 requirements for pressure measurement.

-

Pressure guages

Wika 232.34, 233.34 XSEL™ Process Pressure Gauges

The WIKA® 232.34 and 233.34 XSEL™ process pressure gauges are specifically designed for the chemical and petroleum processing industries. These gauges deliver years of accurate service while withstanding vibration, corrosive media, harsh environments and a wide range of temperature extremes.

-

Pressure guages

Wika 232.50, 233.50 Stainless Steel Pressure Gauges

The WIKA® 232.50 and 233.50 industrial stainless steel pressure gauges are suited for corrosive environments and gaseous or liquid media that will not obstruct the pressure system.

-

Pressure guages

Wika 232.53, 233.53 Stainless Steel Pressure Gauges

The WIKA® 232.53 and 233.53 rugged industrial stainless steel gauges provide resistance to the most corrosive media and most harsh environments. This model features 316 SS wetted parts, 304 SS case and crimped ring, and are field liquid-fillable.

-

Pressure guages

Wika 232.53AM, 233.53AM Refrigeration Ammonia Pressure Gauges

The WIKA® 232.53AM and 233.53AM all stainless steel pressure gauges are specifically designed for refrigeration ammonia applications or other liquid or gaseous media which are compatible with 316 SS and will not obstruct the pressure system.

-

Pressure guages

Wika 232.54, 233.54 Industrial Stainless Steel Pressure Gauges

The WIKA® 232.54 and 233.54 industrial pressure gauges feature 316 SS wetted parts, 304 SS case and bayonet ring, a laminated safety glass window, and can be liquid-filled in the field. They are ideal for process and chemical applications, oil exploration and production, power generation, and pollution control equipment.

-

Pressure guages

Wika 232.54.XMAS Christmas Tree Pressure Gauge

The WIKA® 232.54.XMAS industrial christmas tree gauge is specifically designed for oilfield well heads. It features all stainless steel construction, and large numerals for easier pressure reading.

-

Pressure guages

Wika 233.55 Panel Builders Pressure Gauge

The WIKA® 233.55 lower back mount stainless steel industrial pressure gauge is specifically designed to exact panel builder requirements. This gauge is ideal when used for panel mount gauges in oil and gas, refinery, petrochemical, as well as food and beverage industries.

-

Pressure guages

Wika 262.34, 263.34 XSEL™ Process Pressure Gauges

The WIKA® 262.34 and 263.34 XSEL™ process pressure gauge is specifically designed for chemical and petroleum processing industries. They are engineered to deliver years of accurate service while withstanding vibration, corrosive media, harsh environments and a wide range of temperature extremes.

-

Pressure guages

Wika 312.20 Test Pressure Gauge

The WIKA® 312.20 extremely sensitive, high precision test pressure gauges are excellent for instrument shops, gauge repair and calibration shops, testing laboratories, and other applications demanding highly precise, consistent results. This model features adjustable knife-edge pointers and mirror bands on the dial to assure precise readings.

-

Pressure guages

Wika 332.25 Panel Mount Test Pressure Gauge

The WIKA® 332.25 test pressure gauge meets ASME Grade 3A accuracy standards and features a knife-edge pointer that is easily accessible under the hinged ring front. The gauge is designed for panel mounting, and features 316 SS wetted parts and a one-piece aluminum solid-front safety case.

-

Pressure guages

Wika 332.30, 333.30 Test Pressure Gauge

The WIKA® 332.30 extremely sensitive, highly accurate test pressure gauge features a solid front, blow-out back safety case design, and adjustable knife-edge pointers. The mirror bands on the dial

assure precise readings, and eliminate parallax error. -

Pressure guages

Wika 332.34 Inspector’s Process Test Pressure Gauge

The WIKA® 332.34 industrial high precision inspector’s process test gauge is convenient for on-site testing, and is used for calibration of other measuring instruments. The solid front, blow-out back case design meets safety requirements of ASME B40.100.

-

Pressure guages

Wika 332.34DD Direct Drive Test Pressure Gauge

The WIKA® 332.34DD direct drive test pressure gauge features a direct drive, movementless pressure system. The gauge has a red thermoplastic solid front case, comes equipped with an external zero adjustment, and a high 0.25% full scale accuracy.

-

Pressure guages

Wika 332.54 Inspector’s Stainless Steel Test Pressure Gauge

The WIKA® 332.54 inspector’s test pressure gauge is convenient for field calibrations. They have an accuracy of ±0.25% which meets ASME B40.100 Grade 3A. The mirrored band on the dial, and knife-edge pointer make it easy to take accurate readings. This gauge is also supplied standard with a padded, nylon carrying pouch.

-

Pressure guages

Wika 342.11 Precision Test Pressure Gauge

The WIKA® 342.11 precision test pressure gauge is a high quality, time-proven instrument for applications requiring exceptional precision and high reliability. This test gauge features a bourdon tube made of Ni-Span C® for all pressure ranges above 0-10 psi. Ni-Span C® has exceptional temperature stability, and eliminates the need for an expensive thermal compensator.

-

Pressure guages

Wika 422.12, 432.12 Sealgauge® Diaphragm Pressure Gauges

The WIKA® 422.12 and 432.12 Sealgauge® diaphragm pressure gauges offer superior protection from viscous and crystallizing media. Type 422.12 features carbon steel wetted parts, while type 432.12 offers the corrosion protection of 316 SS wetted parts. Each model is supplied with a black cast iron case, and 1/2″ NPT female connection standard.

-

Pressure guages

Wika 432.50, 433.50 Sealgauge® Diaphragm Pressure Gauges

The WIKA® 432.50 and 433.50 Sealgauge® diaphragm pressure gauges feature all stainless steel construction, and are built to withstand corrosive, highly viscous and cystallizing media. These models are ideal for applications in harsh environments such as pulp and paper processing, chemical, petrochemical, and in water and sewage treatment plants.

-

Pressure guages

Wika 532.52, 532.53, 532.54 Stainless Steel Absolute Pressure Gauges

The WIKA® 532.52, 532.53 and 532.54 stainless steel high overload safety absolute pressure gauges are used when the pressure measurement needs to be carried out independently of fluctuations in the atmospheric pressure.

-

Pressure guages

Wika 611.10, 631.10 Low Pressure Capsule Pressure Gauges

The WIKA® 611.10 and 631.10 low pressure gauges are extremely sensitive and highly accurate. The capsule element pressure system is designed to measure pressure and vacuum of gaseous media from as low as 10″ H2O to 275″ H2O (10 psi). The finely polished nickel-silver pinion gear and shaft of the movement ensure repeatable accuracy.

-

Pressure guages

Wika 612.20 Low Pressure Capsule Pressure Gauge

The WIKA® 612.20 low pressure gauge features a copper alloy capsule element that is designed to measure pressure and vacuum of gaseous media from as low as 2 1/2″ H2O to 275″ H2O (10 psi). The 4″ dial size allows easy reading from a distance. The finely polished nickel-silver pinion gear and shaft of the movement ensure repeatable accuracy.

-

Pressure guages

Wika 612.34, 632.34 Low Pressure Process Pressure Gauges

The WIKA® 612.34 and 632.34 low pressure process gauges offer accurate readings in harsh ambient conditions. They are able to measure the pressure of gaseous media from as low as 10″ H2O to 275″ H2O (10 psi) or other equivalent units of pressure or vacuum. The finely polished nickel-silver pinion gear and shaft of the movement ensure repeatable accuracy.

-

Preassure Instrument

Wika 632.50, 633.50 Low Pressure Capsule Pressure Gauge

The WIKA® 632.50 and 633.50 low pressure gauges offer the corrosion resistance of 316 SS wetted parts, and are able to measure pressure and vacuum of gaseous media from as low as 1″ H2O to 275″ H2O (10 psi). The finely polished nickel-silver pinion gear and shaft of the movement ensure repeatable accuracy.

-

Pressure guages

Wika 700.04 Differential Pressure Gauge

The WIKA® 700.04 piston-style differential pressure gauge is designed for use with clean liquid or gaseous media where high differential pressure/static process pressures are required. This gauge is suitable for measuring pressure drops across a variety of devices, including filters, strainers, separators and heat exchangers.

-

Pressure guages

Wika 700.05 Differential Pressure Gauge

The WIKA® 700.05 diaphragm-style differential pressure gauge is suited for use in applications requiring low to medium differential and medium to high process pressure media. This gauge is intended for measuring pressure drops across filters, strainers, separators, heat exchangers and gas recovery systems.

-

Pressure guages

Wika 711.12, 731.12 Differential Pressure Gauges

The WIKA® 711.12 and 731.12 differential pressure gauges measure pressure differential or duplex measurement of two applied pressures. These gauges are use in HVAC applications, and non-corrosive, non-crystalizing gaseous and liquid media.

-

Pressure guages

Wika 712.15, 732.15 ‘Cryo Gauge’ Differential Pressure Gauges

The WIKA® 712.15 copper alloy and 732.15 stainless steel high-quality and highly innovative differential pressure ‘Cryo Gauges’ are distinguished by their compact and robust design. They are primarily used for liquid level measurement on liquid gas tanks.

-

Pressure guages

Wika 712.25DP Duplex Differential Pressure Gauge

The WIKA® 712.25DP differential pressure gauge with parallel entry features a dual bourdon tube system, and a special subtracting movement drives one pointer to display the differential pressure. The built-in rear flange matches up to existing mounting holes without any modifications.

-

Pressure guages

Wika 712.25DX Duplex Differential Pressure Gauge

The WIKA® 712.25DX differential pressure gauge with parallel entry features two independent pressure systems, and a special movement drives one red pointer and one black pointer to display two pressure readings on the dial. The built-in rear flange matches up to existing mounting holes without any modifications.

-

Pressure guages

Wika 716.11, 736.11 Low Differential Pressure Gauges

The WIKA® 716.11 copper alloy and 736.11 stainless steel low differential pressure gauges measure very low differential pressures from 2.5mbar. Used for differential pressure measurement at measuring points with very low differential pressures, for gaseous, dry, clean, oil and grease free media.

-

Pressure guages

Wika 732.14, 762.14 Differential Pressure Gauges

The WIKA® 732.14 stainless steel and 762.14 monel or hastelloy differential pressure gauges are used in the process industry. A high overload safety is achieved by the all-metal construction, and the close-fitting design of the diaphragm measuring element.

-

Pressure guages

Wika 732.25 Differential Pressure Gauge

The WIKA® 732.25 opposed membrane liquid-filled sensor element differential pressure gauge is for applications requiring high differential, high process pressures. This gauge is used in a variety of industrial applications including rotating equipment systems, and corrosive environments in liquid or gaseous media.

-

Pressure guages

Wika 732.26 Differential Pressure Gauge

The WIKA® 732.26 opposed membrane liquid-filled sensor element differential pressure gauge is for applications requiring low differential, medium static process pressures. The gauge is typically used in a variety of industrial applications including cryogenic gases, and corrosive environments in liquid or gaseous media.

-

Pressure guages

Wika A2G-10 Air2Guide™ Low Pressure Differential Pressure Gauge

The WIKA® A2G-10 Air2Guide™ low pressure differential pressure gauge is designed to measure dry, clean non-aggressive gases and air. It is ideally suited to measure differential pressure in filtration systems, pressure monitoring for HVAC, air handlers and ventilation systems and for pressure monitoring of clean rooms, gas scrubbers and dust collection systems.

-

Pressure guages

Wika A2G-15 Air2Guide™ Low Pressure Differential Pressure Gauge

The WIKA® A2G-15 Air2Guide™ low pressure differential pressure gauge is designed to measure dry, clean non-aggressive gases and air. It is ideally suited to measure differential pressure in filtration systems, pressure monitoring for HVAC, air handlers and ventilation systems and for pressure monitoring of clean rooms, gas scrubbers and dust collection systems.

-

Pressure guages

Wika CPG1500 Digital Pressure Gauge

The WIKA® CPG1500 precision digital pressure gauge combines the accuracy of digital measurement technology, and the simplicity of an analog gauge. In terms of performance, ease-of-use and instrument features, this gauge is unmatched in the pressure measurement market.

-

Pressure guages

Wika CPG500 Digital Pressure Gauge

The WIKA® CPG500 digital pressure gauge enables the measurement and display of pressure values in a single instrument. The accuracy of digital measurement technology, and the simplicity of an analog gauge are combined in this instrument.

-

Pressure guages

Wika M932.D1, M933.D1 Diaphragm Seal Pressure Gauges

The WIKA® M932.D1 and M933.D1 all-welded gauge, diaphragm seal systems are a drop-in retrofit for existing gauges. The assembly eliminates all potential leak paths, and has a tamper-resistant construction. The all-welded system is ideal for installations where tightly controlled fugitive emissions and safety are a concern.