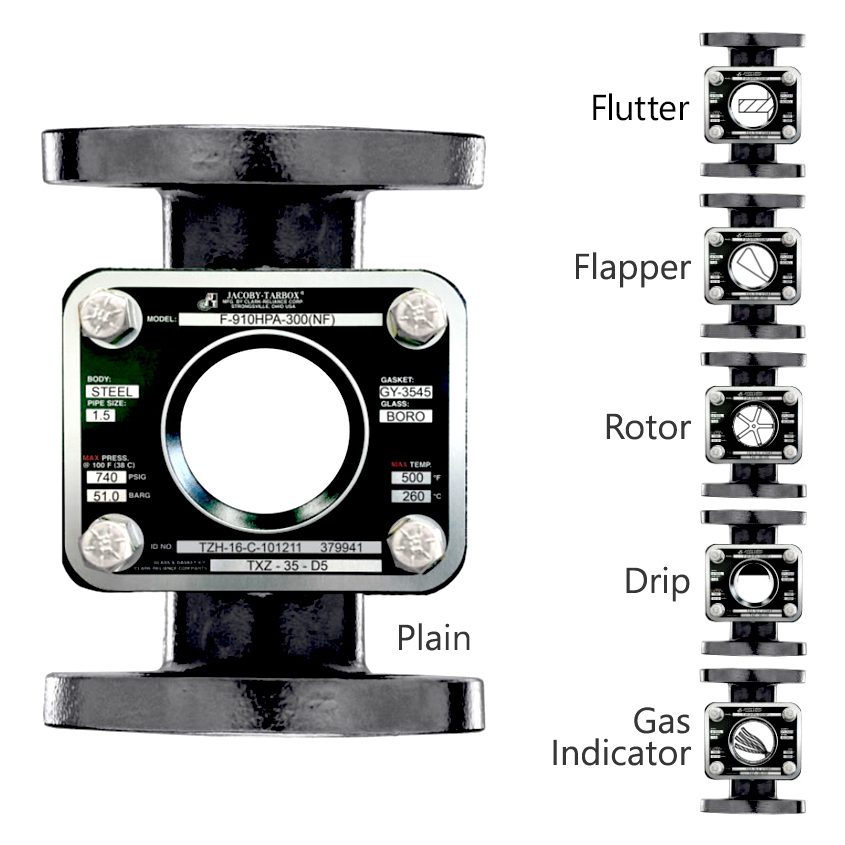

Product Specs

Body Material

316 Stainless Steel

316L Stainless Steel

Alloy 20

Bronze

Carbon Steel

Duplex Stainless Steel

Hastelloy C

Temperature Range

-20°F to 500°F

Indicator

Drip

Flapper

Flutter

Gas Indicator

Plain

Rotor

Size Range

1/2″ -8″

Connections

Flanged

Retainer

A516 GR.70 Steel

Window

Quartz Glass

Tempered Borosilicate

Tempered Borosilicate with UniShield

UniGlas with Duplex Stainless Steel Ring

UniGlas with Hastelloy C Ring

UniGlas with Steel Ring

Seal Gasket

Fiber

Graphite

Gylon 3545

Neoprene

Viton

Cushion Gasket

Fiber

Jacoby-Tarbox High Pressure Flanged Bulls-Eye Sight Flow Indicators, ASME Class 300, 600, 900 & 1500

Jacoby-Tarbox High Pressure Flanged Bulls-Eye Sight Flow Indicators, ASME Class 300, 600, 900 & 1500

The Jacoby-Tarbox line of ASME rated high pressure flanged bulls-eye sight flow indicators are engineered per the design criteria of ASME B31.1 & B31.3, Power and Process Piping Codes, incorporating the listed ASTM materials for all metals in the unit construction.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

acoby-Tarbox ASME flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.