Product Specs

Body Material

316 Stainless Steel

316L Stainless Steel

Alloy 20

Bronze

Carbon Steel

Duplex Stainless Steel

Hastelloy C

Size Range

1/4″ -2″

Temperature Range

-20°F to 500°F

Retainer

316 Stainless Steel (Optional)

Brass (Standard)

Window

Annealed Borosilicate

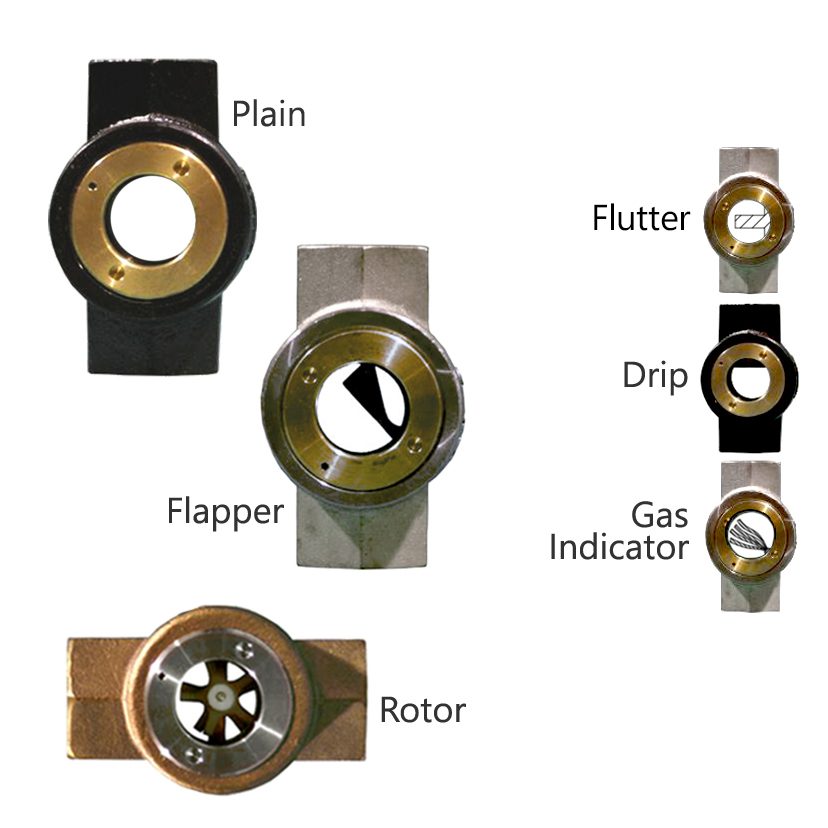

Indicator

Drip

Flapper

Flutter

Gas Indicator

Plain

Rotor

Indicator Applications

Drip: Condensing gasses (drip) or partially full liquid lines

Flapper: Judge flow changes by flapper position

Gas Indicator: Gas flows, low velocity liquid flow in full lines

Plain: Observe presence or absence of fluid

Rotor: Indicates relative process velocity by rotation speed

Flow

Drip: Uni-Directional

Flapper: Uni-Directional

Gas Indicator: Uni-Directional

Plain: Bi-Directional

Rotor: Bi-Directional

Orientation

Drip: Vertical Downward or Horizontal

Flapper: Horizontal or Vertical Upward

Gas Indicator: Horizontal or Vertical Upward

Plain: Horizontal or Vertical

Rotor: Horizontal or Vertical

Connections

Butt Weld

NPT

Socket Weld

Seal Gasket

Fiber

Graphite

Gylon 3545

Neoprene

Viton

Cushion Gasket

Fiber

“ST” 150 psig Model / Code

100-ST / TAA-

100-ST(NF) / TAA-

200-ST / TAB-

300-ST / TAC-

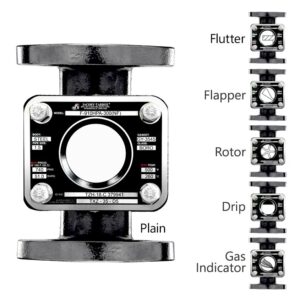

Jacoby-Tarbox Threaded Bulls-Eye Full-View Sight Flow Indicators, ST 150 psig Models

Jacoby-Tarbox Threaded Bulls-Eye Full-View Sight Flow Indicators, ST 150 psig Models

Jacoby-Tarbox’s full line of threaded bulls-eye sight flow indicators have been precisely engineered per the design criteria of ASME to provide either a nominal 150 psig rated unit or a full ASME rated for flow observation and indication. Threaded bullseye sight flows have been engineered per the design criteria of the ASME B31.1 & 31.3 Power & Chemical Piping Codes, incorporating only ASTM listed metals in the unit’s construction. This standard setting group of features include full ASME code compliance with regards to yield criteria, materials, and pressure/temperature ratings.

Pipeline view is maximized, in most cases with a diameter that is equal to the nominal pipe size, allowing 100% unobstructed process observation of gases, solids, solutions, and slurries.

Non-Rotor models offer minimized pressure drops with their non-restricting, smooth, full-bore construction.

Jacoby-Tarbox ASME flanged units are ideal for piping, process, and mechanical engineers that wish to maintain full ASME compliance within their pipelines. Refining, chemical, power, and pharmaceutical industries are just a few areas of Jacoby-Tarbox’s successful code applications. O.E.M.’s specify this series when maximum reliability in harsh operating service is desired.